Avoid Costly Downtime: 12 Critical Mistakes in Magnetic PVC Curtain Installation

A properly installed magnetic PVC strip curtain is a high-ROI asset, boosting energy efficiency, ensuring compliance, and streamlining workflows. However, common installation and specification errors can negate these benefits, leading to premature failure, safety hazards, and significant operational losses. This guide is designed for procurement professionals and facility managers to navigate the critical details of a successful installation. By avoiding these 12 mistakes, you can protect your investment, ensure long-term performance, and achieve the maximum return for your facility.

Mistake 1: Inaccurate Doorway Measurement

The Problem:

Recording imprecise height or width measurements, or failing to account for an unlevel floor or header.

The Consequence:

Curtains that are too short create major energy loss gaps, while curtains that are too long will bunch and curl, causing premature wear and tripping hazards.

The Solution:

Use a steel tape or laser measure to get precise dimensions of the finished opening. Measure width at the top, middle, and bottom, and use the widest figure. Measure height on both the left and right sides. Always provide the *finished opening* dimensions to your supplier.

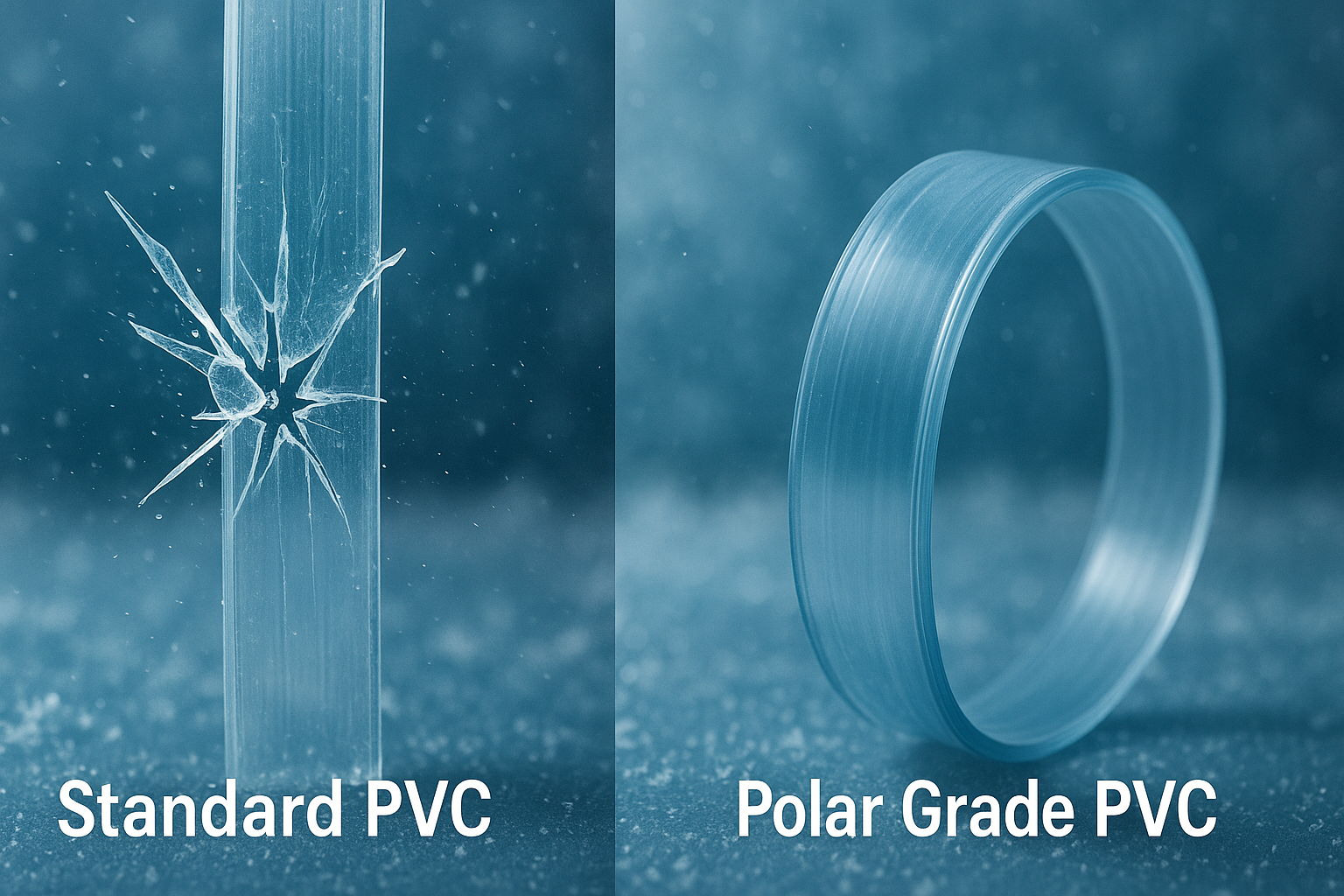

Mistake 2: Specifying the Wrong PVC Material Grade

The Problem:

Using Standard Grade PVC in a sub-zero freezer or walk-in cooler application.

The Consequence:

Standard PVC becomes brittle, cracks, and shatters in cold temperatures, rendering the curtain useless within weeks and creating a foreign material contamination risk in food environments.

The Solution:

Specify Polar (or Low-Temp) Grade PVC for any application operating below 0°C (32°F). This material is formulated to remain flexible down to -40°C/F, ensuring durability and a proper seal.

Mistake 3: Inadequate Strip Thickness and Overlap

The Problem:

Choosing thin strips with minimal overlap for a high-traffic forklift area.

The Consequence:

The strips will tear easily, magnets can be dislodged from impact, and the seal will be insufficient to control temperature or air pressure, defeating the purpose of the curtain.

The Solution:

Match thickness and overlap to traffic. Use `.080"` (2mm) with 50-67% overlap for pedestrian traffic. For heavy forklift or pallet-jack traffic, specify `.120"` (3mm) or `.160"` (4mm) thick strips with 67% or 100% overlap for maximum durability and sealing.

Mistake 4: Selecting the Incorrect Mounting Hardware

The Problem:

Using standard galvanized steel hardware in a food processing area that requires frequent chemical wash-downs.

The Consequence:

The hardware will quickly corrode and rust, creating a hygiene risk and compromising the structural integrity of the entire system.

The Solution:

Use galvanized steel for dry, general-purpose warehouses. For food-grade, pharmaceutical, or high-moisture environments, always specify Stainless Steel (Type 304 or 316) mounting hardware for corrosion resistance and compliance.

Mistake 5: Ignoring Header Integrity and Obstructions

The Problem:

Attempting to install the mounting track on a weak header (e.g., drywall only) or one with obstructions like pipes, conduits, or roll-up door tracks.

The Consequence:

The track can pull away from the wall, causing the entire curtain to fail and creating a serious safety hazard. Obstructions prevent a flush mount, creating large gaps that compromise the seal.

The Solution:

Before ordering, inspect the header to ensure it is structurally sound and can support the curtain's weight. Plan for a wall mount (face mount) as the default. If obstructions are present, discuss in-jamb or custom mounting solutions with your supplier.

Mistake 6: Poor Strip Alignment and Magnetic Polarity

The Problem:

Hanging strips unevenly or with incorrect magnetic polarity, causing magnets to repel instead of attract.

The Consequence:

The curtain will have visible gaps and fail to self-close, completely negating the primary benefit of a magnetic system. Repelling magnets can actively push strips apart.

The Solution:

Hang strips sequentially as they are packaged. Ensure each strip’s magnets properly attract and create a seamless "snap." After hanging, stand on the opposite side and look for light gaps, adjusting the overlap if needed.

Mistake 7: Incorrect Floor Clearance

The Problem:

Cutting strips too short, leaving a gap at the floor, or leaving them too long, causing them to drag excessively.

The Consequence:

A gap at the floor allows for significant energy loss, pest entry, and dust infiltration. Strips that are too long will curl, wear out faster, and can be caught by pallet jacks.

The Solution:

The ideal installation has the bottom of the strips just barely touching or "kissing" the floor. This creates a perfect seal without causing drag or bunching. Account for any sloped floors during measurement.

Mistake 8: Disregarding Traffic Type and Flow

The Problem:

Installing a standard smooth-strip curtain in a doorway with constant, heavy forklift traffic.

The Consequence:

The smooth PVC will quickly become scratched and opaque, severely reducing visibility and creating a major collision risk for operators and pedestrians.

The Solution:

For high-traffic forklift routes, specify ribbed PVC strips. The raised ribs take the impact, preserving the clarity of the main strip body and dramatically extending the safe, functional life of the curtain.

Mistake 9: Failing to Consider Environmental Factors

The Problem:

Installing a standard interior curtain on an exterior-facing loading dock door exposed to high winds or direct sunlight.

The Consequence:

Wind can blow the strips open, rendering the seal useless. Prolonged UV exposure will cause non-UV-stabilized PVC to yellow, haze, and become brittle over time.

The Solution:

For windy areas, use heavier, thicker strips with 100% overlap. For exterior doors, confirm the PVC material is formulated with UV inhibitors to prevent degradation from sunlight.

Mistake 10: Overlooking Long-Term Maintenance & TCO

The Problem:

Focusing solely on the upfront purchase price and not planning for maintenance or the total cost of ownership (TCO).

The Consequence:

Neglecting simple cleaning leads to reduced visibility and hygiene issues. Not having a plan for replacing damaged strips can lead to prolonged periods of poor performance.

The Solution:

Factor in the long-term ROI from energy savings and reduced product spoilage. Establish a simple cleaning schedule. Most importantly, partner with a supplier who offers individual replacement strips to make repairs cost-effective and extend the system's lifecycle.

Mistake 11: Using Improper Cleaning Methods

The Problem:

Cleaning PVC strips with abrasive pads, solvents, or harsh chemical cleaners.

The Consequence:

This will permanently scratch, cloud, or chemically damage the PVC, impairing visibility and potentially voiding food-grade compliance.

The Solution:

Clean strips with a soft cloth and a simple solution of mild soap and water. This maintains transparency, ensures hygiene, and preserves the integrity of the material for its full lifespan.

Mistake 12: Not Planning for Emergency Egress

The Problem:

Assuming the curtain will impede emergency exits or not verifying compliance with local fire codes.

The Consequence:

A non-compliant installation can result in fines and, more critically, could hinder a safe evacuation during an emergency.

The Solution:

PVC strip curtains are designed to be easily pushed through. However, confirm that your chosen configuration does not violate local fire codes for egress paths. Many suppliers also offer fire-retardant PVC that meets standards like NFPA-701 for added safety.

EAV Technical Table: Product Specifications

| Attribute | Specification Details |

|---|---|

| Material Grade | Standard, Polar (Low-Temp), Anti-Static, Anti-Insect (Yellow), Ribbed, Fire-Retardant |

| Certifications | REACH Compliant, RoHS Compliant, Phthalate-Free, FDA Accepted Compounds |

| Thickness/Width Options | Thickness: .080" (2mm), .120" (3mm), .160" (4mm) Width: 8" (200mm), 12" (300mm) |

| Temperature Range | Standard: 0°F to 150°F (-18°C to 66°C) Polar Grade: -40°F to 140°F (-40°C to 60°C) |

| Magnetic Strength | High-Strength Neodymium (N-rating) or Ferrite, RF-welded into waterproof seams |

| Mounting Systems | Material: Galvanized Steel, Stainless Steel (304/316) Type: Wall/Face Mount, In-Jamb Mount, Universal Hook-On System |

B2B Frequently Asked Questions

1. What is the typical ROI for industrial PVC curtains?

In cold storage applications, the ROI can be exceptionally fast, often under 6 months, due to energy savings of over 75% on unsealed doorways. For other applications, ROI is calculated based on reduced product spoilage, improved workflow, and contamination control.

2. How do I specify curtains for a high-traffic forklift area?

For high-traffic forklift areas, we recommend Polar Grade (if cold), .120" or .160" thick ribbed PVC strips with 100% overlap, mounted with heavy-duty stainless steel hardware. This combination ensures maximum durability, visibility, and sealing performance.

3. What are the MOQ and lead times for custom orders?

Minimum Order Quantities (MOQs) and lead times vary based on the complexity and volume of the order. As a direct manufacturer, we offer competitive MOQs and can often expedite production for urgent projects. Contact our sales team with your exact dimensions and requirements for a precise quote and timeline.

4. Can magnetic curtains reduce noise levels?

Yes. The dense PVC material and tight magnetic seal act as an effective acoustic barrier, capable of reducing noise transmission between areas by up to 20 dB, helping facilities meet OSHA noise standards.

5. How do I replace a single damaged strip?

Our systems are fully modular. You can order individual, pre-punched replacement strips to match your original specifications. Simply unhook the damaged strip from the mounting track and hook the new one in its place. This makes repairs fast and highly cost-effective.