The Ultimate Guide to Choosing a Reliable Magnetic PVC Door Curtain Manufacturer

For procurement managers and factory owners, sourcing decisions directly impact the bottom line. Choosing the right industrial door solution is not merely a purchase; it's an investment in efficiency, safety, and compliance. While standard PVC strip doors offer a basic barrier, they often fail to deliver the robust performance required in demanding environments. This guide provides a comprehensive framework for identifying and vetting a reliable magnetic PVC door curtain manufacturer, ensuring you secure a partner that delivers maximum ROI through superior engineering and factory-direct value.

Why Standard Strip Curtains Fail in Demanding Environments

Before investing, it's crucial to understand the limitations of traditional solutions. Standard, non-magnetic strip curtains, while inexpensive upfront, often introduce significant operational costs and risks over their lifecycle.

The Inevitable Gaps of Gravity-Fed Systems

Standard strips rely solely on gravity to hang in place. This passive design is easily compromised by air pressure differentials, drafts, and the simple act of passage. Strips can sway, settle improperly, or stick together, creating persistent gaps that undermine the very purpose of the barrier.

The Hidden Costs of Energy Loss and Contamination

These gaps lead to constant thermal exchange. In a cold storage facility or climate-controlled warehouse, this translates directly to higher energy consumption as HVAC and refrigeration systems work harder to maintain temperature. Furthermore, these openings allow dust, pests, and airborne contaminants to infiltrate, compromising product quality and hygiene.

How High Traffic Exacerbates Performance Issues

In high-traffic zones with constant forklift and personnel movement, the shortcomings of gravity-fed systems are magnified. The continuous disruption prevents strips from ever forming a consistent seal, rendering them largely ineffective and leading to premature wear and tear from constant impacts.

The Superior Engineering of Magnetic PVC Door Curtains

The key to overcoming these challenges lies in a proactive design. Magnetic PVC curtains introduce an active closing mechanism that delivers a fundamentally higher level of performance and reliability.

Deconstructing the Self-Closing Magnetic Seal

The innovation is elegantly simple: industrial-grade magnets are hermetically sealed along the vertical edges of each PVC strip. When a person or vehicle passes through, the strips part easily and then automatically snap back together, drawn by the magnetic force to create a complete seal from top to bottom.

The Role of Magnet Strength and Encapsulation

A high-quality manufacturer uses powerful neodymium or ferrite magnets, appropriately spaced for optimal attraction. Crucially, these magnets are RF-welded into waterproof seams. This encapsulation prevents moisture intrusion and corrosion, which is essential for longevity in wash-down environments or freezers.

Achieving a Hands-Free, Near-Airtight Barrier

This self-closing system ensures the integrity of the environmental barrier is maintained with minimal human intervention. It provides a consistent, reliable, and hands-free solution that actively works to control temperature, hygiene, and airflow, making it far superior to passive, non-magnetic alternatives.

Calculating the Total Cost of Ownership (TCO) and ROI

A strategic procurement decision looks beyond the initial invoice. While magnetic PVC curtains may have a higher upfront cost than standard strips, their TCO is significantly lower, delivering a rapid and measurable return on investment.

A Financial Model for Quantifying Energy Savings

The most direct ROI comes from energy conservation. An unsealed doorway in a refrigerated environment can account for a significant portion of the cooling load. By creating a superior thermal barrier, magnetic curtains can reduce doorway-related energy loss by over 75%, leading to immediate reductions in utility bills and a payback period often under 12 months.

Impact on Productivity, Workflow, and Cycle Times

In logistics and manufacturing, time is money. Hands-free passage eliminates the need for forklift drivers to stop, dismount, and manually operate doors. This creates a seamless workflow, shortens cycle times, and boosts overall operational productivity. The improved visibility of transparent curtains also reduces the risk of costly collisions.

Beyond Upfront Price: Maintenance, Durability, and Product Spoilage

The TCO calculation must include savings from reduced product spoilage (due to better temperature and contaminant control), lower maintenance on HVAC systems, and the extended lifespan of a durable, well-engineered product. Focusing on TCO ensures you are choosing the most cost-effective solution for the long term.

Material Science: Selecting the Right PVC for Your Application

The performance of a magnetic curtain is defined by the quality of its materials. A reliable manufacturer will offer a range of options and provide expert guidance on selecting the right one for your specific operational environment.

The Critical Choice: Standard vs. Low-Temp (Polar) Grade PVC

This is a non-negotiable decision based on temperature. Standard Grade PVC is suitable for ambient temperatures from approximately 0°F to 150°F (-18°C to 66°C). Low-Temp (Polar) Grade PVC is essential for any freezer or sub-zero application. It is specially formulated with plasticizers to remain flexible down to -40°F/C. Using standard PVC in a freezer will cause it to become brittle and crack, leading to complete system failure.

Analyzing Strip Thickness and Overlap for Durability

For areas with heavy forklift and pallet jack traffic, thicker strips (e.g., .120" or 3mm) offer greater resistance to tearing and impact. The percentage of overlap between strips—from a standard 50% to a maximum-seal 100%—should be increased for larger doorways or those exposed to high wind or significant pressure differentials.

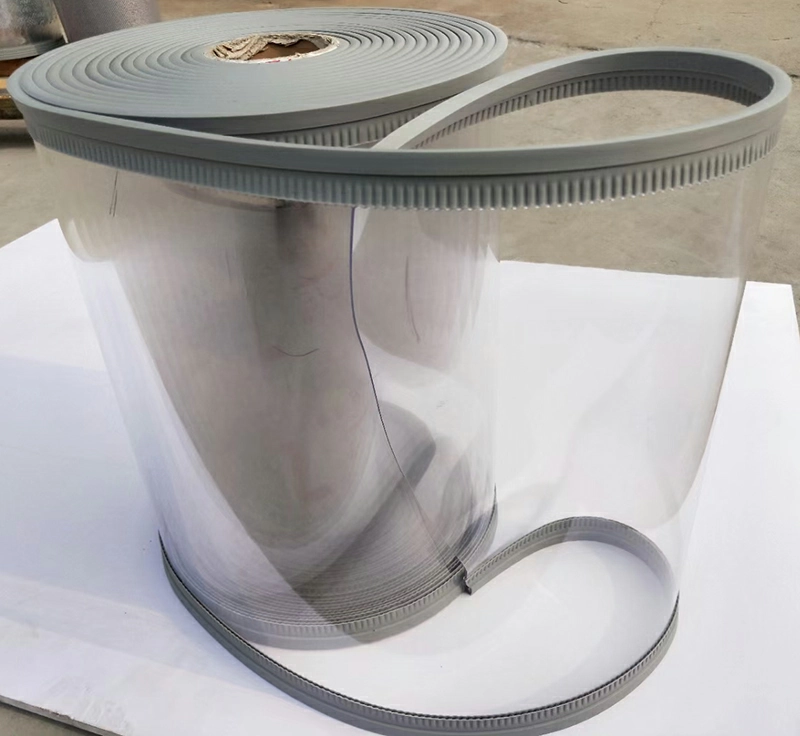

Ribbed vs. Smooth Strips: A Guide to Longevity and Visibility

Smooth Strips offer perfect, glass-like clarity, ideal for pedestrian-only traffic. Ribbed Strips are designed with raised ridges that take the brunt of impacts from forklifts and pallets. This design significantly reduces scratching on the main body of the strip, preserving visibility and extending the product's functional lifespan in high-traffic routes.

Evaluating a Manufacturer's Production and OEM Capabilities

The most significant value in B2B procurement comes from partnering directly with the source. Assessing a manufacturer's capabilities is key to a successful long-term relationship.

The Strategic Advantage of Factory-Direct Sourcing

Sourcing directly from an Original Equipment Manufacturer (OEM) cuts out intermediary markups, leading to substantial cost savings, especially on bulk orders. A factory-direct relationship also provides direct access to technical expertise and ensures greater control over the final product.

Assessing OEM/ODM Services for Custom-Sized Solutions

Industrial facilities rarely have uniform openings. A competent manufacturer will offer robust OEM/ODM (Original Design Manufacturer) services, allowing you to specify exact dimensions, material grades, colors, and even add branding. This is crucial for non-standard doorways, conveyor openings, and unique partitioning needs.

Verifying Production Technology and Capacity for Bulk Orders

Inquire about their manufacturing processes. Do they use modern extrusion lines and high-frequency RF welding for magnet encapsulation? What is their production capacity and typical lead time for bulk orders? A transparent manufacturer will readily share this information, demonstrating their ability to handle large-scale, consistent supply.

Vetting for Quality: Compliance, Certifications, and Standards

Certifications are not just logos; they are verifiable proof of a manufacturer's commitment to quality, safety, and environmental responsibility. They are a critical tool for risk mitigation in your supply chain.

Decoding Key Certifications: REACH, RoHS, and ISO 9001

ISO 9001 indicates the manufacturer has a robust Quality Management System in place for consistent production. REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is a European Union regulation ensuring materials are safe for human health and the environment. RoHS (Restriction of Hazardous Substances) certifies that the product is free from specific hazardous materials like lead and cadmium.

Ensuring Food-Grade Compliance (FDA, USDA, NSF)

For any application in the food and beverage industry, materials must be certified as safe for incidental contact with food products. Look for manufacturers who can provide PVC that meets FDA, USDA, or NSF standards. This is a non-negotiable requirement for HACCP compliance.

Requesting Material Specification Sheets and Third-Party Test Reports

Don't just take their word for it. A reputable manufacturer will provide detailed technical data sheets (TDS) for their materials, outlining properties like temperature range, tensile strength, and chemical resistance. Ask for copies of their certification documents and any relevant third-party test reports.

Application Spotlight: Cold Storage and Food Processing Facilities

In temperature- and hygiene-sensitive environments, magnetic PVC curtains are a critical operational tool that directly impacts safety and profitability.

Preserving the Cold Chain and Reducing Defrost Cycles

The superior seal of magnetic curtains drastically reduces the infiltration of warm, moist air into freezers and coolers. This stabilizes internal temperatures, protects the integrity of the cold chain, and leads to fewer and shorter defrost cycles, saving significant energy and reducing wear on refrigeration equipment.

Supporting HACCP Plans and Integrated Pest Management (IPM)

A tight-sealing magnetic curtain is a critical control point in any HACCP plan. It acts as a formidable physical barrier against insects, rodents, and airborne microbes, preventing cross-contamination. This is the first line of defense in an effective IPM program, reducing reliance on chemical pest control.

Selecting Hardware: Stainless Steel vs. Galvanized Steel

The mounting hardware is just as important as the strips. For any food processing area or wash-down environment, Grade 304 Stainless Steel is mandatory due to its corrosion resistance. For dry industrial or warehouse applications, galvanized steel is a cost-effective and durable alternative.

Application Spotlight: Warehouses, Logistics, and Manufacturing

In high-traffic industrial settings, magnetic curtains enhance safety, workflow, and environmental control, contributing to a more efficient and compliant operation.

Enhancing Forklift Safety with Superior Visibility

Safety is paramount. High-quality transparent PVC strips provide a clear line of sight, allowing forklift operators and pedestrians to see potential hazards on the other side of the doorway before passing through. This simple feature can dramatically reduce the risk of dangerous and costly collisions.

Noise Abatement for OSHA Compliance and Worker Comfort

The dense PVC material and tight magnetic seal create an effective acoustic barrier. Installing these curtains between loud production areas and quieter zones can reduce noise transmission by 15-20 dB, helping facilities comply with OSHA noise exposure limits and creating a more comfortable work environment.

Controlling Dust, Fumes, and Cross-Contamination Between Zones

Magnetic curtains are an excellent and cost-effective way to create partitioned zones within a larger facility. They effectively contain dust from cutting or grinding operations, control fumes from welding, and prevent cross-contamination between different manufacturing stages, all while allowing for easy traffic flow.

Navigating the Supply Chain: From Quote to Delivery

A smooth procurement process relies on clear communication and a partnership approach with your chosen manufacturer.

Best Practices for Requesting a Comprehensive Quote (RFQ)

Your RFQ should be as detailed as possible. Include the exact dimensions of each opening, the required PVC grade (Standard/Polar), strip thickness, desired overlap, hardware material (Stainless/Galvanized), and quantity. Providing this level of detail ensures you receive an accurate and comparable quote.

Understanding Lead Times, Packaging, and International Shipping

Clarify production lead times for your order size. Ask how the curtains will be packaged (e.g., individual kits, bulk rolls on pallets) to ensure they arrive undamaged. If sourcing internationally, discuss Incoterms (e.g., FOB, CIF) to understand shipping responsibilities and costs clearly.

Managing Bulk Orders for Multi-Facility Consistency

For companies with multiple sites, establishing a single-source OEM relationship is highly strategic. It ensures product consistency, simplifies part reordering for maintenance, and leverages purchasing power for better pricing. Work with the manufacturer to create standardized SKUs for your common door sizes.

Installation and Lifecycle Management Best Practices

The long-term value of your investment depends on proper installation and simple, consistent maintenance.

A Pre-Installation Checklist for Facility Managers

Before installation, verify the finished opening dimensions. Inspect the header area above the doorway to ensure it is level, structurally sound, and free of obstructions like conduits or sprinkler pipes that could interfere with the mounting track.

Wall Mount vs. In-Jamb: Choosing the Right Hardware System

Wall Mount (Face Mount) is the most common and effective method. The track is mounted on the wall above the opening, allowing the strips to cover the entire opening for the best possible seal. In-Jamb Mount (Header Mount) is used when there is insufficient wall space above the opening. The track is mounted underneath the door header.

Creating a Maintenance Schedule for Cleaning and Wear Inspection

Periodically clean the PVC strips with mild soap and water to maintain transparency and hygiene. Avoid harsh chemical cleaners. Regularly inspect the strips—especially at the bottom and near the mounting points—for tears or significant wear. The modular nature of the system allows for the easy and cost-effective replacement of individual damaged strips.

Comparative Analysis: Magnetic Curtains vs. Alternative Door Solutions

To make an informed decision, it's essential to weigh magnetic curtains against other common industrial door solutions.

Cost-Benefit Analysis: High-Speed Roll-Up Doors

High-speed roll-up doors provide an excellent seal but come with an extremely high initial cost, require electricity and complex sensors, and involve expensive, specialized maintenance. For most internal applications, magnetic curtains offer 80-90% of the sealing performance at less than 20% of the total cost.

Energy and Contaminant Control: Air Curtains

Air curtains (air doors) use a high-velocity stream of air to create an invisible barrier. While they can separate temperatures, they are energy-intensive and do nothing to stop the passage of physical contaminants like dust, insects, or noise. Magnetic curtains provide a physical barrier that stops all these elements while consuming zero energy.

Seal Integrity: Standard Non-Magnetic Hook-On Strips

This is the most critical comparison. The active, self-closing magnetic seal provides consistently superior performance over non-magnetic strips, which inevitably gap and leak energy. In any application where temperature, hygiene, or environmental separation is a primary concern, the enhanced seal integrity of a magnetic system provides a far greater return on investment.

Your Final Procurement Checklist for a Reliable Manufacturer

Use this three-step process to finalize your sourcing decision and choose a partner that will deliver lasting value.

Step 1: Document Your Exact Operational Requirements

For each doorway, document the dimensions, temperature environment, traffic type and volume, and specific contaminants to be controlled (dust, pests, noise). This forms the basis of your technical specification.

Step 2: Create a Shortlist of Vetted OEM Suppliers

Identify 3-5 potential manufacturers. Verify their OEM capabilities, ask for proof of key certifications (ISO, REACH, RoHS), and request customer references or case studies relevant to your industry.

Step 3: Issue a Detailed RFQ and Evaluate Total Value

Submit your detailed RFQ to your shortlisted suppliers. When comparing quotes, look beyond the price per unit. Evaluate the quality of the materials proposed, the warranty offered, the clarity of their communication, and their ability to be a long-term strategic partner. Choose the manufacturer that offers the best overall value, not just the lowest initial price.

EAV Technical Specification Table

| Entity | Attribute | Value |

|---|---|---|

| PVC Material | Grade | Standard, Polar (Low-Temp), Ribbed, Anti-Static, Anti-Insect (Yellow) |

| Thickness | .080" (2mm), .120" (3mm), .160" (4mm) | |

| Width Options | 8" (200mm), 12" (300mm), 16" (400mm) | |

| Performance | Temp. Range (Standard) | 0°F to 150°F / -18°C to 66°C |

| Temp. Range (Polar) | -40°F to 140°F / -40°C to 60°C | |

| UV Resistance | Formulated with UV inhibitors for sunlight exposure | |

| Sound Reduction | Up to 20 dB, depending on thickness and overlap | |

| Construction | Magnet Type | Neodymium or Ferrite, RF-welded into waterproof seams |

| Hardware Material | Galvanized Steel (Standard), Stainless Steel 304 (Food/Pharma Grade) | |

| Mounting Options | Wall Mount (Face Mount), In-Jamb (Header Mount), Universal Mount | |

| Overlap Options | 50% (Standard), 67% (Heavy Duty), 100% (Maximum Seal) | |

| Compliance | Certifications | REACH Compliant, RoHS Compliant, Phthalate-Free options available |

| Food/Health Safety | FDA 21 CFR, USDA accepted materials available | |

| Fire Retardancy | CFM, NFPA-701, M2 standards available |

Frequently Asked Questions

What are the benefits of magnetic PVC strip curtains over regular ones?

The primary benefit is the self-closing magnetic seal. This creates a superior, gap-free barrier that significantly improves energy efficiency and contaminant control compared to standard, non-magnetic curtains which rely on gravity and often hang open.

Are PVC strip curtains energy efficient?

Yes, especially magnetic ones. By creating a tight thermal seal over doorways in climate-controlled areas like warehouses and cold storage, they can reduce energy loss by over 75%, leading to substantial savings on heating and cooling costs.

What is the best type of PVC curtain for a warehouse?

For a general warehouse with forklift traffic, the best choice is typically a ribbed, standard-grade magnetic PVC curtain with a thickness of .120" (3mm) and a 67% or 100% overlap. The ribbed profile protects against scratches, ensuring long-term visibility and safety.

What thickness of PVC strip curtain is best?

It depends on the traffic. For pedestrian-only areas, .080" (2mm) is sufficient. For heavy forklift and pallet jack traffic, a thicker strip of .120" (3mm) or .160" (4mm) is recommended for increased durability and resistance to wear and tear.

How do I verify a PVC strip curtain supplier?

To verify a supplier, especially a manufacturer, ask for their ISO 9001 certification to confirm quality management processes. Request documentation for material compliance like REACH and RoHS. For food applications, demand proof of FDA or USDA-compliant materials. Finally, ask for references or case studies from businesses in your industry.

Can I get custom-sized PVC strip curtains?

Yes. A reputable manufacturer will offer OEM (Original Equipment Manufacturer) services to produce curtains to your exact dimensional specifications. This is essential for non-standard openings, large bays, and conveyor systems to ensure a perfect fit and optimal seal.