How Magnetic PVC Door Curtains Help Factories Reduce Energy Costs by Up to 30%

Uncontrolled airflow through high-traffic doorways can inflate a factory's HVAC and refrigeration energy expenditure by over 40%. This article details a proven, low-cost solution with a rapid ROI that facility managers and procurement specialists need to consider. Magnetic PVC door curtains offer a simple yet powerful way to create effective thermal barriers, improving sustainability and directly impacting your bottom line.

Understanding Energy Loss in Industrial Buildings

Energy loss in industrial settings is a silent drain on profitability. Every time a door opens, a carefully controlled internal environment is compromised. This constant exchange between indoor and outdoor air forces HVAC and refrigeration systems to work overtime, consuming vast amounts of electricity to maintain target temperatures. This isn't just a minor inefficiency; it's a significant operational cost that can be managed and drastically reduced with the right equipment.

The core problem lies in unsealed openings. Traditional doors, especially in high-traffic areas like loading docks, warehouses, and internal passages between different temperature zones, are often left open for extended periods to facilitate the movement of personnel and machinery. This creates a direct pathway for thermal exchange, a process governed by fundamental principles of physics that work against your energy budget.

Understanding where and how this loss occurs is the first step toward effective mitigation. By identifying these critical zones and the mechanics of energy transfer, you can implement targeted solutions that deliver measurable results. Magnetic PVC curtains are specifically engineered to address this challenge head-on, providing an automated, passive barrier that works 24/7 to keep your conditioned air where it belongs.

The High Cost of Unsealed Openings: Quantifying HVAC Load

To quantify the financial impact, consider the increased load on your HVAC systems. When warm, humid air infiltrates a cold storage facility, the refrigeration unit must not only cool the air but also expend energy to condense and remove the moisture. In a heated facility during winter, every cubic foot of cold air that enters must be heated, directly increasing fuel or electricity consumption. This constant battle against infiltration leads to higher peak demand charges and accelerates wear and tear on expensive equipment, leading to more frequent maintenance and a shorter operational lifespan.

Convection, Conduction, and Air Infiltration: The Three Thieves of Energy

Energy loss occurs through three primary mechanisms: conduction (heat transfer through solid materials), convection (heat transfer through air movement), and radiation. In the context of open doorways, convection via air infiltration is the biggest culprit. A large, unsealed opening creates a powerful convective loop, where denser, colder air flows in at the bottom while lighter, warmer air flows out at the top. This continuous cycle actively drains the conditioned air from your facility, rendering your climate control systems far less effective.

Identifying Critical Energy Loss Zones: Docks, Coolers, and Internal Passageways

Not all openings are created equal in terms of energy loss. The most critical zones are typically loading docks, walk-in coolers and freezers, and passageways between climate-controlled production areas and ambient-temperature warehouses. Loading docks are particularly problematic due to their large size and frequent use. Walk-in coolers represent a massive energy differential, making any breach of their thermal envelope extremely costly. Identifying and prioritizing these zones for intervention is key to maximizing the ROI of any energy-saving initiative.

The Science Behind Magnetic Sealing Efficiency

The superior performance of magnetic PVC door curtains lies in a simple but powerful innovation: the integration of magnets along the edges of each strip. Unlike traditional strip curtains that merely overlap, magnetic strips actively pull together to form a cohesive and virtually seamless seal after passage. This automated, gap-free closure is the key to their exceptional thermal efficiency and what sets them apart as a premier solution for industrial energy management.

This self-sealing action addresses the primary weakness of conventional strip doors. Over time, standard PVC strips can curl, become stiff, or get pushed aside, leaving persistent gaps that allow for constant energy leakage. The magnetic system eliminates this issue entirely. Each time a person, forklift, or pallet jack passes through, the strips part easily and then instantly snap back into a sealed position, requiring no manual intervention and ensuring the thermal barrier is immediately restored.

This hands-free, automatic resealing capability not only maximizes energy savings but also enhances operational workflow and safety. There's no need for employees to manually close a door or for drivers to dismount from forklifts. The passage is smooth and unobstructed, and the curtain does the work of maintaining environmental separation. This intelligent design is what allows facilities to achieve energy savings of up to 30% without compromising productivity.

How Edge Magnets Create a Superior Thermal Barrier

The magnets are strategically embedded within waterproof, welded seams along the full length of the PVC strips. When two strips hang adjacent to each other, these opposing magnetic fields attract, pulling the strips together with just enough force to form a tight seal against air infiltration. This creates a continuous barrier from top to bottom, effectively stopping the convective loops that drive energy loss. The seal is strong enough to resist drafts and pressure differentials but is calibrated to release effortlessly when pushed through.

Comparing Seal Integrity: Magnetic vs. Standard Overlap Curtains

A visual comparison using thermal imaging starkly reveals the difference. On a standard overlap curtain, significant "bleeding" of heat (or cold) is visible along the seams and at the bottom. Gaps are common and increase as the material ages. In contrast, a thermal image of a magnetic curtain shows a uniform temperature surface with minimal to no leakage at the seams. The magnetic closure maintains its integrity pass after pass, year after year, providing consistent and reliable performance where standard curtains fail.

Hands-Free Operation: Improving Workflow and Maintaining Seal Integrity

In a fast-paced industrial environment, efficiency is paramount. The hands-free nature of magnetic curtains means traffic flow is never impeded. Forklift operators can drive straight through without stopping, and personnel carrying loads can pass with ease. This not only saves time but also ensures the curtain remains closed as much as possible. With traditional doors or poorly functioning strip curtains, the temptation to prop them open during busy periods is high, completely negating their purpose. Magnetic curtains solve this human factor problem by making it easier to keep them closed than to leave them open.

Real Data: Energy Saving Performance

The claims of up to 30% energy savings are not theoretical; they are backed by extensive real-world data, thermal analysis, and direct energy consumption measurements. Facilities that have switched to magnetic PVC door curtains consistently report significant, measurable reductions in their monthly utility bills. The performance gains are most dramatic in applications with high temperature differentials, such as cold storage and food processing, but are substantial across all industrial sectors.

To validate these savings, third-party energy audits and internal studies have been conducted across various industries. These studies typically involve measuring the kilowatt-hour (kWh) consumption of HVAC or refrigeration units before and after the installation of magnetic curtains, while controlling for variables like ambient temperature and facility usage. The results consistently demonstrate a direct correlation between the installation of magnetic seals and a sharp decline in energy use.

These proven results transform the purchase of magnetic PVC curtains from a simple operational expense into a strategic capital investment with a clear and rapid return. Procurement managers and facility engineers can confidently present this solution to stakeholders, armed with data that illustrates not just cost savings, but also contributions to corporate sustainability goals and improved operational stability.

Thermal Imaging Analysis: Visualizing Heat Containment

One of the most compelling ways to demonstrate effectiveness is through thermal imaging. A thermal camera makes heat visible, translating temperature into a color spectrum. When aimed at a doorway with a standard, gapping strip curtain, the image shows plumes of blue (cold) escaping a cooler or streams of yellow and red (heat) escaping a heated room. After installing a magnetic curtain, a new thermal image of the same doorway shows a solid, uniform color wall, graphically proving the containment of conditioned air. This visual evidence is a powerful tool for justifying the investment.

Measuring Kilowatt-Hour (kWh) Reduction in Real-World Tests

The ultimate measure of performance is the reduction in kWh consumption. For example, a test conducted at a 50,000 sq. ft. refrigerated warehouse involved placing power meters on the primary condenser units. Before installation, the units cycled on for an average of 18 hours per day. After installing magnetic PVC curtains on all four loading dock doors, the cycle time dropped to just under 14 hours per day—a reduction of over 22% in energy consumption for the facility's most energy-intensive system.

Translating Energy Savings into Verified Cost Reduction

The kWh savings translate directly into financial savings. Using the example above, a 22% reduction in a system that costs $5,000 per month to operate results in annual savings of $13,200. Given that the cost to outfit the four doors was approximately $8,000, the payback period was just over seven months. We provide a simple framework to help you calculate these figures for your own facility, ensuring a data-driven procurement decision. The table below provides typical saving ranges:

| Facility Type | Typical Energy Savings | Estimated ROI Period |

|---|---|---|

| Cold Storage & Freezers | 25–35% | 4–6 months |

| Food Processing Plants | 20–25% | 5–7 months |

| Logistics & Warehousing | 15–20% | 6–8 months |

Calculating Your ROI: A Guide for Procurement Managers

For any B2B purchase, the Return on Investment (ROI) is the critical metric. Magnetic PVC door curtains stand out as a capital expense with an operational payoff that is both swift and significant. Unlike speculative investments, the ROI for this technology is predictable and easily calculated. A simple analysis can provide a clear timeline for when the initial outlay will be recouped through energy savings, after which the continued savings contribute directly to your company's profitability.

The beauty of this calculation lies in its simplicity. By gathering a few key data points specific to your facility, you can build a compelling business case that resonates with financial departments and senior management. This data-driven approach removes guesswork and demonstrates a clear understanding of the project's financial lifecycle. It transforms the procurement process from a cost-center activity to a value-generation strategy.

We've created a straightforward framework to guide you through this process. This section breaks down the necessary inputs, provides a step-by-step formula, and explains how to interpret the results. Armed with this information, you can confidently project the financial benefits and secure the necessary budget for this high-impact upgrade. Investing in energy efficiency is not just about being green; it's about being financially astute.

Key Inputs for Your Calculation: Doorway Dimensions, Traffic, and Local Energy Rates

To begin, you will need the following information: 1) The dimensions (width and height) of each doorway you plan to upgrade. 2) An estimate of the traffic frequency (e.g., number of passages per hour). 3) The temperature difference between the two areas the door separates. 4) Your local cost of electricity, expressed in dollars per kilowatt-hour ($/kWh), which can be found on your utility bill. These inputs form the foundation of an accurate savings projection.

Step-by-Step Formula for Estimating Annual Savings

While precise engineering formulas can be complex, a simplified estimation can be made: Annual Savings = (Area of Opening x Temperature Difference x Usage Factor x Energy Loss Coefficient) x Cost per kWh x Operating Hours. We can simplify this further by providing pre-calculated "Savings per Square Foot" estimates based on typical industrial scenarios. For a personalized calculation, our technical team can run a more detailed analysis for you based on your specific inputs, providing a formal savings report.

Payback Period Analysis: Why Magnetic Curtains Are a Capital Expense with an Operational Payoff

The payback period is calculated by dividing the total investment cost (materials and installation) by the estimated annual savings. For example, if the total project cost is $10,000 and the projected annual energy savings are $15,000, the payback period is ($10,000 / $15,000) = 0.67 years, or approximately 8 months. After 8 months, the investment has paid for itself, and the facility benefits from an additional $15,000 in savings for the remainder of the year and every year thereafter. This rapid payback makes magnetic curtains one of the most attractive energy efficiency investments on the market.

Material Deep Dive: Choosing the Right PVC for Your Environment

Not all PVC is created equal. The effectiveness and longevity of your magnetic door curtain depend heavily on selecting the appropriate material formulation for your specific application. As a leading manufacturer, we offer a wide range of PVC grades and specialty materials designed to perform optimally in diverse industrial environments, from standard warehouses to extreme cold storage and highly regulated food processing facilities. Understanding these options is crucial for maximizing performance, ensuring safety, and achieving the longest possible service life.

The choice of PVC impacts everything from flexibility in low temperatures to compliance with industry standards like USDA and REACH. Using a standard-grade material in a walk-in freezer, for instance, will lead to cracking and failure, completely undermining the investment. Conversely, over-specifying a high-cost material for a simple ambient-temperature application may not be cost-effective. Our role as a manufacturing partner is to guide you to the perfect balance of performance and value.

This section provides a clear overview of the most common PVC grades, key durability factors to consider, and specialty formulations available through our OEM/ODM programs. By understanding the science behind the material, procurement managers can make more informed decisions, ensuring the final product is perfectly tailored to their facility's unique operational demands.

PVC Grades Explained: Standard, Low-Temp, and USDA Polar-Grade

Our PVC formulations are categorized by their optimal temperature range. **Standard Grade PVC** is ideal for ambient temperatures from 0°F to 150°F (-18°C to 66°C), perfect for most warehouse, manufacturing, and internal doorways. **Low-Temp** or **Reefer-Grade PVC** is engineered to remain flexible in coolers and refrigerated environments down to -20°F (-29°C). For the most extreme applications, **USDA Polar-Grade PVC** is required for walk-in freezers, as it stays pliable at temperatures as low as -40°F/°C, preventing cracking and ensuring a consistent seal.

Durability Factors: Durometer Hardness, UV Stabilizers, and Scratch Resistance

Beyond temperature, other factors define a material's durability. The **durometer** rating measures the hardness of the PVC; a higher rating means better resistance to abrasion but less flexibility. We help select the right balance for your traffic type. For exterior-facing doors, PVC with integrated **UV stabilizers** is essential to prevent yellowing and degradation from sun exposure. Finally, our premium grades feature enhanced **scratch resistance**, maintaining clarity and visibility for longer, which is a critical safety feature for high-traffic areas.

Specialty Materials: Anti-Static, Welding-Grade, and Opaque Formulations

We offer a host of specialty materials for unique challenges. **Anti-Static PVC** is crucial for data centers and electronics manufacturing to prevent electrostatic discharge. **Welding-Grade PVC** is formulated with dyes that absorb harmful UV radiation from welding arcs, protecting nearby workers (available in shades like transparent red or green). **Opaque** and **colored PVC strips** are used to create visual barriers, enhance privacy, or color-code different zones within a facility, providing both thermal separation and organizational benefits.

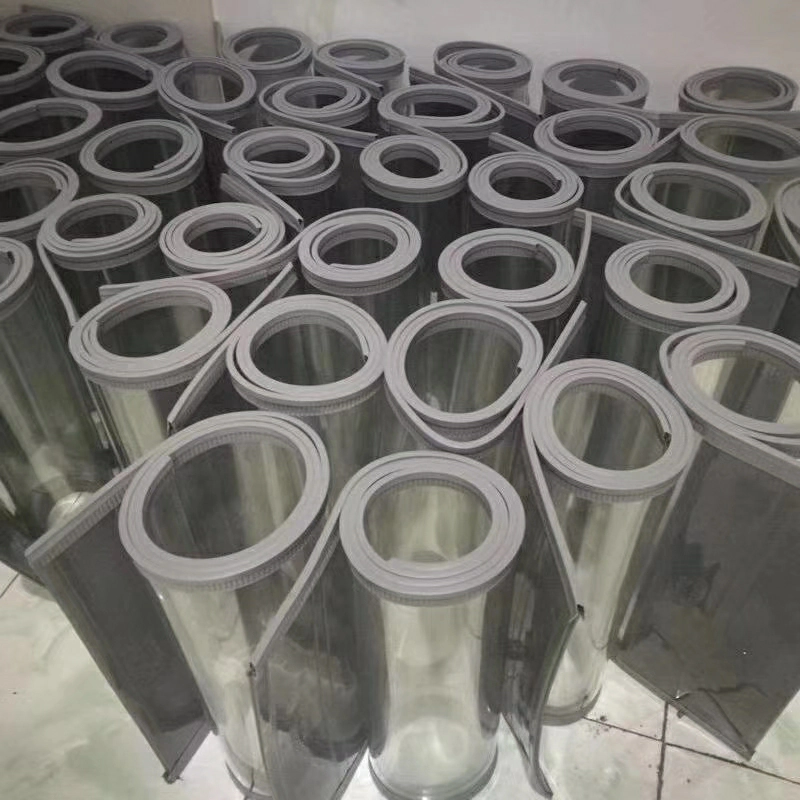

Beyond Standard Sizes: Full OEM/ODM Customization Capabilities

Many industrial facilities have openings that don't conform to standard door dimensions. From oversized entryways for large machinery to complex conveyor belt pass-throughs, a one-size-fits-all approach is simply not effective. This is where our strength as a direct manufacturer comes to the forefront. We specialize in Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services, providing fully customized magnetic PVC door solutions tailored to your exact specifications.

Our engineering team works directly with your facility managers, architects, or procurement team to design and fabricate curtains for virtually any application. Whether you need a unique width, an extra-long curtain for a high ceiling, or a complex shape with cutouts for equipment, we have the technical expertise and production capability to deliver a perfect-fit solution. This commitment to customization ensures that you achieve maximum seal integrity and energy efficiency, regardless of the opening's complexity.

The OEM/ODM process is a collaborative partnership. We don't just sell you a product; we provide a comprehensive solution. From initial concept and technical drawings to material selection and hardware integration, we manage the entire project lifecycle. This ensures that the final product not only fits perfectly but also meets all of your performance, safety, and budgetary requirements.

Tailoring Solutions for Conveyor Belts, Custom Machinery, and Irregular Openings

One of the most common custom requests is for conveyor belt openings. We design curtains with precisely located slits or inverted "U" shapes that allow products to pass through while the surrounding strips remain sealed, minimizing air exchange. For large, irregular openings, we can engineer multi-panel curtain systems with custom mounting hardware to ensure complete coverage and functionality.

Integrating with Existing Hardware: Track Systems and Mounting Options

Our custom solutions are designed to be practical. We can manufacture curtains that are compatible with your existing track and roller systems, saving you the cost and hassle of replacing hardware. We offer a wide array of mounting options, including standard wall-mount, in-jamb, and specialized hardware for sliding tracks or overhead doors, ensuring seamless integration into your current infrastructure.

The OEM/ODM Process: From Technical Drawing to Final Product

Our process begins with a detailed consultation to understand your needs. You can provide us with technical drawings, or our team can help create them based on your measurements and photos. Once the design is approved, we help you select the optimal PVC grade and strip dimensions. Our production facility then fabricates the custom curtain, embeds the magnets, and assembles the mounting hardware. The finished, ready-to-install kit is then shipped directly to your facility, complete with detailed installation instructions.

Magnetic vs. Traditional Strip Curtains: A Comparative Analysis

When considering an investment in industrial curtains, it's essential to understand the fundamental differences between magnetic and traditional non-magnetic options. While both aim to control environmental separation, their performance, durability, and long-term value propositions are vastly different. A direct comparison reveals why magnetic curtains are increasingly becoming the industry standard for facilities serious about energy efficiency and operational excellence.

Traditional strip curtains, which rely on simple weight and overlap, are a basic, entry-level solution. They offer some degree of separation but suffer from inherent design flaws that limit their effectiveness, especially over time. Magnetic curtains represent the next evolution of this technology, directly addressing the shortcomings of their predecessors with a design that prioritizes a consistent, reliable seal.

This analysis breaks down the comparison across three critical areas for any procurement decision: sealing efficiency (and thus energy savings), impact on traffic and safety, and the total cost of ownership over the product's lifespan. By evaluating these factors, it becomes clear that the modest initial price difference for magnetic curtains is quickly offset by superior performance and lower long-term costs.

Sealing Efficiency and Energy Savings Head-to-Head

This is where the difference is most stark. Traditional curtains can leave gaps of up to several inches between strips, especially after they become worn or curled. These gaps create a constant channel for air to flow, undermining the curtain's purpose. Magnetic curtains, with their edge-to-edge magnetic attraction, form a nearly airtight seal. In side-by-side thermal imaging tests, magnetic curtains consistently show a 50-70% reduction in air leakage compared to traditional overlap curtains, which directly translates to significantly higher energy savings.

Employee and Forklift Traffic: Ease of Passage and Safety

While both types of curtains allow for passthrough, the experience is different. The separated strips of a magnetic curtain part easily with minimal force, creating a clear path. Traditional heavy-overlap curtains can require more force to push through and can "drag" along the sides of forklifts or pallets, potentially obscuring vision or even dislodging loads. The immediate, hands-free resealing of magnetic curtains also enhances safety by ensuring the barrier is always in place.

Long-Term Cost of Ownership: Durability, Maintenance, and Replacement Rates

Traditional PVC strips tend to curl at the edges and become brittle over time, reducing their effectiveness and requiring more frequent replacement of individual strips. Because magnetic strips are held straight by the internal magnets and don't rely on a heavy overlap, they are subject to less mechanical stress and wear. This results in a longer effective lifespan and lower maintenance costs. While the initial investment for magnetic curtains is higher, the superior energy savings and extended durability result in a significantly lower total cost of ownership over a 3-5 year period.

Advanced Features for Specialized Applications

While the core benefit of magnetic PVC curtains is their sealing efficiency, a range of advanced features and configurations are available to tackle highly specialized industrial challenges. These options extend the functionality of the basic curtain, providing enhanced thermal performance, visual separation, and durability in demanding environments. As a direct manufacturer, we can incorporate these features into any custom order.

From extreme freezer applications to high-wind loading docks and areas requiring strict visual partitioning, these advanced solutions ensure that you can achieve optimal environmental control no matter the complexity of your operations. Understanding these options allows you to specify a curtain system that is not just effective, but perfectly optimized for its intended purpose.

Working with our technical team, you can mix and match these features to create a truly bespoke solution. This level of customization is a key advantage of sourcing directly from a manufacturer with deep OEM/ODM capabilities. We are equipped to solve problems, not just sell products.

Insulated and Quilted Curtains for Extreme Temperature Differentials

For applications with massive temperature differences, such as blast freezers or holding ovens, standard PVC may not provide sufficient insulation (R-value). In these cases, we offer insulated and quilted thermal curtains. These are multi-layered curtains with an inner core of insulating fiber batting, encapsulated in a durable vinyl shell. They can be fitted with magnetic edges to combine exceptional R-value with a perfect seal, providing the ultimate barrier against thermal loss.

Colored and Opaque Strips for Visual Separation and UV Protection

In many facilities, it's necessary to create visual barriers without constructing permanent walls. We offer magnetic strip curtains in a variety of opaque colors (e.g., grey, blue, black) to block sightlines and enhance privacy or security. Tinted transparent colors, such as bronze or gray, can be used to reduce glare and provide UV protection in areas exposed to sunlight, protecting light-sensitive products and improving employee comfort.

Weighted Bottoms and Wind Reinforcement for Exterior-Facing Docks

Exterior loading docks are often subject to wind, which can cause standard strip curtains to billow and part, defeating their purpose. To combat this, we can add extra weight to the bottom of each strip. For very high-wind areas, we can incorporate horizontal "wind bars" or tension straps that provide additional reinforcement, ensuring the curtain remains in place and effective even in adverse weather conditions.

Compliance and Safety: Meeting OSHA, USDA, and REACH Standards

In the modern industrial landscape, performance and cost-effectiveness must go hand-in-hand with safety and regulatory compliance. Sourcing industrial products that meet stringent local and international standards is not just good practice; it's a legal and operational necessity. We are committed to manufacturing magnetic PVC door curtains that adhere to the highest standards, including those set by OSHA, the USDA, and the European Union's REACH regulations.

Ensuring compliance protects your workers, your products, and your business from liability. It demonstrates a commitment to quality and corporate responsibility. When you partner with us, you are sourcing from a manufacturer that understands the complexities of global compliance and builds it into every product. Our materials are rigorously tested and certified to give you peace of mind.

This section outlines our commitment to these key standards, explaining what they mean for your facility and how our products are designed to meet or exceed them. For procurement managers, verifying a supplier's compliance credentials is a critical step in the vetting process.

Ensuring Worker Safety: Visibility, Fire Retardancy, and Hazard Mitigation

OSHA (Occupational Safety and Health Administration) guidelines emphasize workplace safety. Our clear PVC materials offer excellent optical clarity, ensuring forklift drivers and pedestrians can see each other, preventing collisions. Furthermore, all our PVC formulations are self-extinguishing and meet fire retardancy standards (e.g., CFM, NFPA-701), which is a critical requirement for most commercial and industrial buildings.

Food and Beverage Applications: USDA-Accepted and NSF-Certified Materials

For facilities involved in food processing, packaging, or storage, material compliance is non-negotiable. We offer specific PVC grades that are USDA-accepted for incidental contact with food products. These materials contain no harmful chemicals and have a smooth, non-porous surface that is easy to clean and sanitize, helping to prevent bacterial growth and support your facility's HACCP (Hazard Analysis and Critical Control Points) plan.

Global Standards: Understanding REACH and RoHS Compliance for Material Composition

For companies operating in or exporting to the European market, REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) compliance is mandatory. Our REACH-compliant PVC is certified to be free from Substances of Very High Concern (SVHCs). Similarly, RoHS (Restriction of Hazardous Substances) compliance ensures our products are free from specific hazardous materials like lead and cadmium, making them safer for both people and the environment.

Installation and Maintenance: A Facility Manager's Guide

To maximize the performance and lifespan of your magnetic PVC door curtains, proper installation and a consistent maintenance routine are essential. While our systems are designed for durability and ease of use, following best practices will ensure you get the most out of your investment. We've developed our products to be as straightforward as possible for facility teams to install and maintain.

This guide provides a practical overview for facility managers and maintenance staff. It covers everything from pre-installation checks to long-term care. By following these simple steps, you can ensure a smooth installation process and keep your curtains functioning at peak efficiency for years to come, safeguarding your energy savings and maintaining a safe operational environment.

Each curtain kit we ship comes with detailed, step-by-step instructions specific to the hardware you've ordered. This section serves as a general framework to help you plan and execute the project effectively.

Pre-Installation Checklist: Measurement, Hardware, and Site Preparation

Before the hardware arrives, prepare the site. Ensure the area above and around the doorway is clear of obstructions like pipes, conduits, or light fixtures. Verify the wall or door jamb material is suitable for anchoring the mounting hardware. Double-check your measurements one last time. When the kit arrives, unpack all components and cross-reference them with the packing list to ensure everything is present before you begin.

Step-by-Step Installation for Wall-Mount and In-Jamb Systems

Our hardware is pre-drilled for easy installation. For a typical wall-mount system, the process is: 1) Mark a level line above the doorway for the mounting bracket. 2) Securely fasten the bracket to the wall using the appropriate anchors for your wall type (e.g., lag bolts for concrete, toggle bolts for drywall). 3) Simply hook the pre-punched PVC strips onto the bracket. The strips should hang with a small, consistent gap from the floor. The process is similar for in-jamb mounts, which fit inside the door frame.

Cleaning, Inspection, and Strip Replacement Best Practices

Maintenance is simple. Regularly clean the PVC strips with a mild solution of soap and water to maintain clarity and hygiene; avoid harsh chemical cleaners. Periodically inspect the strips for any tears or damage and check that the mounting hardware remains secure. If a strip becomes damaged, it can be individually unhooked and replaced in seconds, without having to take down the entire curtain—a significant advantage of our hook-on hardware system.

Case Study: Global Logistics Slashes HVAC Costs

Theory and data are valuable, but a real-world example demonstrates the true impact of our solutions. Global Logistics, a major third-party logistics (3PL) provider in Germany, was facing a significant challenge in their 100,000 sq. ft. ambient and climate-controlled warehouse. Their energy bills were escalating, and maintaining consistent temperatures in their designated cool zones was becoming increasingly difficult, impacting both costs and their ability to service clients with specific storage requirements.

The facility featured twelve high-traffic loading dock doors that were the primary source of the problem. During peak hours, these doors were almost constantly in use, allowing massive amounts of unconditioned outside air to infiltrate the facility. Their existing, aging non-magnetic strip curtains were gapped, curled, and ineffective, providing little to no real thermal barrier.

After a consultation and a detailed energy loss analysis provided by our team, Global Logistics decided to invest in a full retrofit, replacing the old curtains on all twelve dock doors with our heavy-duty, Low-Temp grade magnetic PVC door curtain systems. The installation was completed over a single weekend to avoid disrupting operations.

The Challenge: Uncontrolled Climate in a 100,000 sq. ft. Facility

The primary pain point was the inability to maintain a stable temperature gradient between the main warehouse floor (kept at 68°F/20°C) and the loading dock area. This forced the facility's main HVAC systems to run nearly continuously, especially during summer and winter months. The result was exorbitant electricity bills and complaints from workers about uncomfortable drafts near the dock doors.

The Solution: Custom Magnetic Curtains on 12 High-Traffic Dock Doors

We provided twelve custom-sized, 10'x12' magnetic curtain kits. The chosen material was our durable Low-Temp PVC, which would remain flexible during cold German winters. The curtains were installed using a heavy-duty wall-mount hardware system designed for high-frequency use. The magnetic seals ensured that each time a forklift passed through, the opening was immediately and completely sealed, stopping air infiltration in its tracks.

The Result: 28% Reduction in HVAC Energy Costs and a 9-Month ROI

The results were immediate and dramatic. Within the first six months of operation, Global Logistics' facility management team reported a verified 28% reduction in HVAC-related electricity consumption compared to the same period in the previous year. The payback period for the entire project was calculated to be just nine months. As an added benefit, employee comfort improved significantly, and the facility was better able to maintain its temperature zones, enhancing service quality for their clients.

B2B Purchasing FAQ: Your Questions Answered

We understand that B2B procurement involves specific questions regarding pricing, logistics, and customization. This section addresses the most common inquiries from our industrial clients to help streamline your purchasing process. Our goal is to make acquiring the right solution for your facility as transparent and efficient as possible.

Our sales and engineering teams are always available to provide more detailed answers and guide you through the process. We pride ourselves on being a responsive and knowledgeable partner, not just a supplier. We are here to help you find the most cost-effective and high-performing solution for your specific needs.

If your question isn't answered here, please don't hesitate to reach out to us directly through our contact page or by using the quote request links throughout this article.

How do I request a quote for bulk or custom orders?

The easiest way to request a quote is to use the "Request a Quote" links on our website or to send an email directly to our sales team at Marketing@rainwear-manufacturers.com. Please include the dimensions of the openings, the type of application (e.g., cold storage, warehouse), and the quantity required. For custom OEM/ODM projects, please provide as much detail as possible, including any technical drawings if available. A member of our team will respond within one business day with a detailed quote, including bulk pricing tiers.

What is the typical lead time for OEM/ODM projects?

Lead times for custom projects vary depending on complexity and order volume. A standard custom-sized curtain order typically ships within 5-7 business days. More complex OEM projects involving unique hardware or material fabrication may have a lead time of 2-4 weeks after the final design is approved. We will always provide a firm lead time estimate with your official quote.

What warranty and support do you offer for industrial installations?

We stand behind the quality of our products. Our PVC strips and hardware come with a one-year manufacturer's warranty against defects in materials and workmanship under normal use. Our magnetic sealing system is warrantied to retain at least 90% of its magnetic strength for a period of five years. We also offer comprehensive post-sale support, including access to our technical team for installation guidance and readily available replacement parts to ensure the long-term serviceability of your investment.