Case Study: Magnetic Door Curtains vs. Sliding Doors in Industrial Warehouses — Which Performs Better?

Setting the Stage: The Critical Role of Doorways in Warehouse Operational Efficiency

Defining the Key Performance Indicators (KPIs) for Warehouse Doors

In the complex ecosystem of a modern industrial warehouse, every component impacts the bottom line. Yet, doorways—the literal gateways for all workflow—are often overlooked as mere openings rather than critical operational assets. This oversight can be costly. An inefficient doorway is not just a passage; it's a constant drain on resources, a bottleneck in productivity, and a weak point in environmental control. For facility managers and procurement specialists, selecting the right industrial warehouse door solutions is a high-stakes decision that directly influences profitability, safety, and sustainability.

Evaluating a warehouse door goes far beyond its initial price. A strategic procurement decision is based on a holistic view of performance, measured by specific KPIs:

- Energy Efficiency: The door's ability to maintain climate zones and minimize thermal loss, measured by R-value, U-value, and air leakage rates.

- Total Cost of Ownership (TCO): A comprehensive calculation including upfront cost, energy consumption, maintenance expenses, and projected lifespan.

- Operational Throughput: The speed and ease with which personnel and equipment can pass through, measured in cycle times.

- Durability & Reliability: The door's resistance to wear, impact, and environmental factors, minimizing downtime.

- Safety & Compliance: Adherence to standards like OSHA for visibility and egress, and FDA/HACCP for contaminant control.

How Inefficient Doors Impact Your Bottom Line: Beyond the Obvious

The financial drain from a poorly chosen door extends into multiple operational areas:

- Spiraling Energy Costs: Gaps and slow cycle times in climate-controlled areas force HVAC and refrigeration systems to work harder, leading to inflated utility bills.

- Productivity Loss: Slow, manual, or frequently malfunctioning doors create bottlenecks, delaying forklift traffic and disrupting the continuous flow of goods.

- Increased Maintenance Burden: Doors with complex mechanical parts or less resilient materials require frequent, costly repairs and unscheduled downtime.

The B2B Procurement Challenge: Balancing Cost, Performance, and Longevity

The central challenge in any B2B procurement guide for industrial doors is finding the equilibrium between initial investment and long-term value. A cheaper door might save capital today but cost multiples more over its lifecycle in energy, maintenance, and lost productivity. The goal is to invest in a solution that delivers the lowest TCO and the highest ROI analysis for industrial doors. This case study dissects two dominant solutions—Magnetic PVC Curtains and Traditional Sliding Doors—to provide a clear framework for this critical decision.

Solution Profile: The Technology Behind Magnetic Door Curtains

The Science of the Self-Closing Magnetic Seal

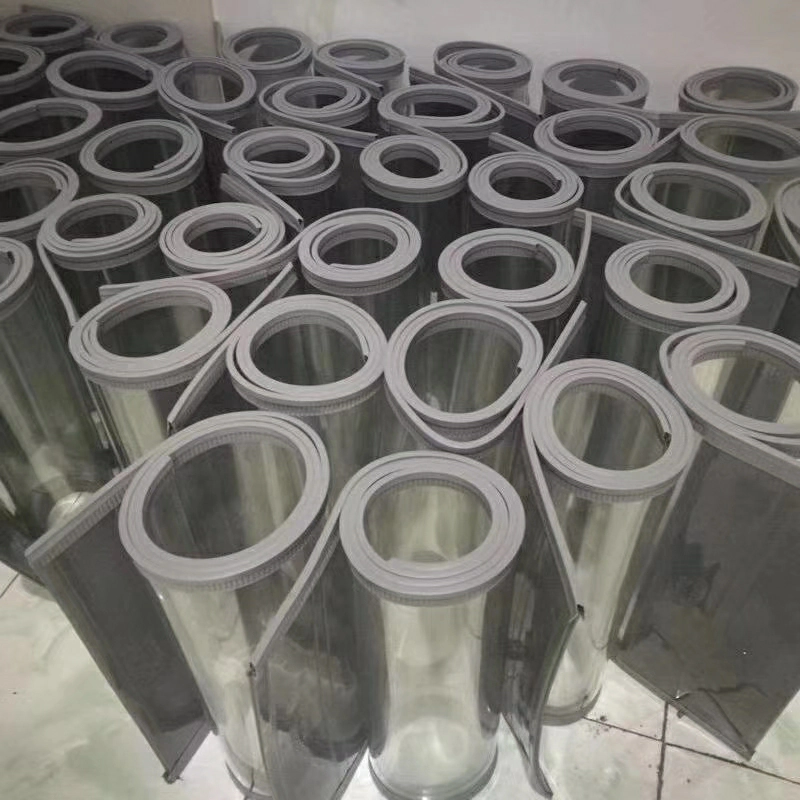

Magnetic door curtains represent an evolution of the traditional vinyl strip door, engineered specifically to overcome the common failure points of gravity-hung systems. They are a flexible, intelligent solution designed for high-traffic industrial door efficiency.

The core innovation is the integration of high-strength magnets along the edges of each PVC strip. When personnel or a forklift passes through, the strips part easily and then instantly snap back together, creating a complete, gap-free seal from top to bottom. Unlike traditional strips that can be pushed aside and fail to reset, this active magnetic closure ensures the integrity of the thermal barrier for warehouse doorways is maintained after every passage.

🏭 Contact Us for a Technical QuoteKey Materials: From Polar Grade PVC to Heavy-Duty Ribbed Strips

The performance of a magnetic curtain is determined by its material composition. Procurement specifications often include:

- Standard Grade PVC: Ideal for internal doorways separating ambient temperature zones.

- Polar (or Low-Temp) Grade PVC: Remains flexible and resists cracking in temperatures as low as -40°F, making it essential for walk-in coolers and freezers.

- Ribbed PVC: Features raised ribs on the strip surface to absorb impact and reduce scratching from forklift and pallet jack traffic, significantly extending the curtain's lifespan and maintaining visibility.

- Anti-Static & Fire-Retardant Grades: For specialized environments like data centers or areas with combustible materials.

Why Hands-Free Operation is a Game-Changer for High-Traffic Zones

In a busy warehouse, every second counts. The hands-free nature of magnetic curtains eliminates the need for personnel to stop and manually open a door or wait for a slow mechanical cycle. This frictionless passage is a cornerstone of warehouse workflow optimization, allowing for:

- Uninterrupted forklift and pedestrian traffic.

- Reduced risk of collisions with a partially open door.

- Improved safety, as drivers' hands remain on the controls.

Solution Profile: The Mechanics of Industrial Sliding Doors

Manual vs. Automated High-Speed Sliding Systems: A Comparison

Industrial sliding doors are a robust, traditional solution known for security and their ability to span large openings. They operate horizontally on a track system, making them a space-efficient choice where swing radius is a concern.

Manual Sliding Doors: Simple, durable, and lower in upfront cost. They are best suited for openings with infrequent use, as the time and effort required to open and close them manually can impede workflow in high-traffic areas.

🏭 Contact Us for a Technical QuoteAutomated High-Speed Sliding Doors: Feature powerful motors and sensors (motion, loop detectors) for rapid opening and closing. They are designed for high-cycle environments to maximize throughput and minimize air exchange, but come with a higher initial cost and greater mechanical complexity.

Material Breakdown: Galvanized Steel, Aluminum, and Insulated Panels

The construction of sliding doors is key to their durability and performance: Galvanized Steel, Aluminum, and Insulated Panels. An insulated sliding warehouse door features a core of polyurethane or polystyrene foam sandwiched between steel or aluminum skins. This design provides a significant thermal break, crucial for exterior walls and climate-controlled zones.

Understanding Track Systems, Power Requirements, and Space Constraints

Procurement must account for the physical requirements of a sliding door system. A key consideration is the need for sufficient wall space adjacent to the opening for the door to slide into when open. The track system must be robust enough to support the door's weight and withstand industrial use. Automated systems also require a dedicated power source and professional electrical installation.

Energy Efficiency Deep Dive: A Thermal Performance Showdown

Quantifying Air Leakage: Comparing Sealing Effectiveness

Air leakage is the number one enemy of climate control. Magnetic Curtains: The floor-to-ceiling magnetic seal actively closes any gaps, minimizing air infiltration to near zero when static. This results in an estimated 75% or greater reduction in energy loss compared to an unprotected opening. Sliding Doors: While high-quality sliding doors have perimeter gaskets, achieving a perfect, airtight closure is mechanically challenging. Gaps can persist along the track and floor.

🏭 Contact Us for a Technical QuoteInsulation Metrics: U-Value and R-Value in Sliding Doors vs. Thermal Barriers

An insulated sliding door's performance is measured by its R-value. A higher R-value indicates better insulation. However, this value only applies when the door is *fully closed*. A magnetic curtain's effectiveness is more about preventing air exchange (*convection*), which is the primary driver of energy loss in high-traffic doorways. In practice, this prevention of convection often delivers greater real-world cost savings on industrial warehouse doors.

Case Study Data: Impact on HVAC Load and Energy Consumption

Data from facilities that have retrofitted openings with magnetic PVC curtains consistently shows a dramatic reduction in HVAC/refrigeration unit run times. In cold storage applications, facilities report energy consumption reductions of 30-50% after installing magnetic curtains on high-traffic doorways, demonstrating a direct correlation between sealing effectiveness and energy savings. While an insulated sliding door also reduces consumption compared to an uninsulated door, its slower cycle times and potential for air gaps limit its peak efficiency in busy zones.

Total Cost of Ownership (TCO) & ROI Analysis: A Head-to-Head Financial Comparison

Calculating Upfront Investment: Hardware, Customization, and Labor Costs

Magnetic Curtains: Have a significantly lower upfront cost. The hardware is simpler, and installation is fast, often completed in hours by in-house maintenance staff. Sliding Doors: Represent a major capital expenditure. The cost includes heavy door panels, a complex track system, and for automated versions, motors and sensors. Installation is a complex process requiring specialized technicians.

🏭 Contact Us for a Technical QuoteLong-Term Savings Model: Energy Bill Reduction vs. Higher Initial Outlay

This is where the financial models diverge. Sliding Doors justify their high initial cost with the promise of robust security and longevity. Magnetic Curtains offer a compelling model based on rapid ROI. The significant and immediate reduction in energy bills, combined with the low upfront cost, means the system often pays for itself in under a year. This makes industrial PVC curtain energy savings a powerful lever for reducing operational expenses quickly.

Payback Period Analysis for Different Warehouse Scenarios

Cold Storage / Food Processing: In environments with a high temperature differential, magnetic curtains have an extremely short payback period, often 6-12 months. High-Traffic Loading Dock (Internal): Magnetic curtains offer a faster ROI due to their low cost and workflow benefits. External Security Opening: A heavy-duty insulated sliding door is the only viable option for primary external security.

| Attribute | Magnetic PVC Curtain | Traditional Sliding Door |

|---|---|---|

| Upfront Cost | Low ($500 - $2,500) | High to Very High ($5,000 - $25,000+) |

| Installation Time | 1-3 hours (often by in-house staff) | 1-3 days (requires professional crew) |

| Energy Savings | Excellent (stops convection) | Good to Excellent (with insulation) |

| ROI / Payback Period | Very Fast (often < 18 months) | Slow to Moderate (3-7 years) |

| Maintenance Cost | Low (periodic cleaning) | Moderate to High (mechanical checks) |

| Security Level | Low (visual deterrent only) | Very High (robust physical barrier) |

Operational Workflow & Traffic Management: Impact on Productivity

Cycle Time Analysis: Forklift and Personnel Passage Speeds

An efficient warehouse is in constant motion. The right door solution facilitates flow, while the wrong one creates friction and eats into productive hours.

Magnetic Curtains: Offer a near-zero cycle time. A forklift or person can pass through without slowing down. The self-closing seal eliminates waiting time. Sliding Doors: Even high-speed models have a defined cycle time (e.g., 5-10 seconds to open, a pause, and 5-10 seconds to close). In a high-traffic area, this waiting time accumulates into hours of lost productivity.

🏭 Contact Us for a Technical QuoteVisibility and Collision Prevention: A Critical Safety Comparison

Magnetic Curtains: Standard clear PVC provides full visibility, allowing drivers to see oncoming traffic and pedestrians, drastically reducing the risk of collisions at blind corners. Sliding Doors: Are opaque. While small vision panels can be added, they offer a limited field of view. This necessitates additional safety measures like warning lights or horns.

Noise Abatement Properties of Curtains vs. Solid Doors

Both solutions offer noise reduction benefits. A solid, insulated sliding door will block more decibels when closed. However, a magnetic PVC curtain provides consistent noise dampening between work areas without impeding traffic flow.

Maintenance, Durability, and Lifecycle Costs: Which Solution Endures?

Scheduled Maintenance Protocols and Associated Labor Costs

Durability is not just about surviving, but about maintaining performance with minimal intervention. Here, the two solutions present a clear trade-off between mechanical complexity and material simplicity.

Sliding Doors: Require a regular professional maintenance schedule. This includes lubricating rollers, checking cable tension, inspecting and servicing the motor, and verifying sensor functionality. These warehouse door maintenance costs add up. Magnetic Curtains: Maintenance is simple and can be handled by internal staff. It primarily involves wiping the strips clean to maintain visibility.

🏭 Contact Us for a Technical QuoteComparing Component Wear: Tracks and Rollers vs. PVC Strips

Sliding Doors: The most common failure points are mechanical. Rollers wear out, tracks can be damaged by impacts, and motors and sensors can fail. Magnetic Curtains: The component that experiences wear is the PVC strip itself. A direct forklift tine impact might gouge or tear a strip.

The Advantage of Modularity: Replacing Strips vs. Door Panel Repair

This is a key differentiator in lifecycle cost. If a sliding door panel is significantly damaged by a forklift, the entire panel often needs to be replaced—a costly repair. If a PVC strip on a magnetic curtain is damaged, you simply slide the single strip off the mounting track and slide a new one on. The repair takes minutes and costs a fraction of a panel replacement.

Safety & Compliance Analysis: Meeting OSHA, FDA, and Environmental Standards

Pest, Dust, and Contaminant Control for FDA & HACCP Environments

For food processing, pharmaceutical manufacturing, and cleanrooms, preventing contamination is non-negotiable. The tight, active magnetic seal of a PVC curtain provides a superior barrier against airborne dust, contaminants, and insects compared to the passive brush seals on a sliding door, helping facilities meet strict FDA and HACCP standards.

Meeting OSHA Visibility, Egress, and Workplace Safety Requirements

OSHA places a strong emphasis on workplace safety. The high visibility of clear magnetic curtains directly supports OSHA's goal of preventing struck-by accidents involving forklifts and pedestrians. While solid sliding doors can be compliant, they require additional safety systems to compensate for their lack of visibility.

🏭 Contact Us for a Technical QuoteFire Retardancy Ratings and Material Safety Considerations

Both solutions are available with fire-retardant material options. PVC for curtains can be specified to meet various fire codes, and the core materials of insulated sliding doors are typically fire-resistant. Procurement teams must verify that the chosen product meets local building and fire code requirements.

Application-Specific Performance: Cold Storage vs. High-Volume Loading Docks

Best Use Case: Magnetic Curtains for Internal Climate Separation & Cleanrooms

Magnetic PVC curtains excel as internal partitions where maintaining environmental separation and high traffic flow are the primary goals. Ideal for: Walk-in Coolers & Freezers, Cleanroom & Wash-down Areas, and Noise & Fume Barriers.

Best Use Case: Sliding Doors for External Security & Large Vehicle Access

Heavy-duty sliding doors are the definitive choice for external openings that demand high security and must withstand weather. Perfect for: Primary Loading Dock Doors and Large-Scale Equipment Entry.

🏭 Contact Us for a Technical QuoteHybrid Solutions: When to Use Both in a Single Facility for Maximum Benefit

The smartest facilities often use a hybrid approach. A heavy-duty insulated sliding door serves as the primary external security barrier on the loading dock. Just inside this door, a magnetic PVC curtain is installed. The sliding door is opened at the beginning of the day and closed at the end, while the magnetic curtain manages climate control and workflow throughout the shift. This combines the security of the rigid door with the energy and operational efficiency of the flexible curtain.

Customization & Scalability: Tailoring Solutions for Unique Facility Needs

Sourcing Custom-Sized Solutions for Non-Standard Openings

Standard solutions don't fit every warehouse. The ability to customize a door system is a critical factor for project engineers and architects. Both magnetic curtains and sliding doors can be custom-manufactured to fit virtually any opening size. The key difference is complexity and cost. Custom-sizing a magnetic curtain is a relatively straightforward process, whereas a custom oversized sliding door is a significant engineering project.

Integration with Access Control, Sensors, and Automation Systems

Sliding doors offer deep integration possibilities with sophisticated building automation systems, including badge readers and remote security monitoring. Magnetic curtains, by their nature, are a passive, hands-free system and do not require this level of integration.

🏭 Contact Us for a Technical QuoteAesthetic and Branding Considerations for Modern Facilities

For modern facilities, especially those with public-facing areas, aesthetics can be important. Sliding doors can be finished in a wide variety of colors and styles. While magnetic curtains are primarily functional, options like colored or opaque strips can be used to match branding or delineate specific zones.

Installation Showdown: A Practical Look at Deployment Time and Complexity

Comparing Installation Complexity and Required Professional Expertise

Magnetic Curtain Installation: Can typically be performed by a competent in-house maintenance team. The process involves mounting a track and hanging the pre-sized strips. It requires basic tools and minimal training. Sliding Door Installation: Is not a DIY project. It requires a team of certified professional installers to mount the heavy tracks, hang the door panels, and wire the electronics.

Site Preparation Checklist: Header Integrity, Electrical, and Wall Space

For Sliding Doors: The site needs significant preparation. The header must have sufficient structural integrity to support the door weight. The adjacent wall must be clear. Dedicated electrical power must be run to the location. For Magnetic Curtains: Site preparation is minimal. The installer simply needs to confirm the header is sound enough to hold the lightweight track.

🏭 Contact Us for a Technical QuoteDowntime Analysis: How Long Will Your Doorway Be Out of Commission?

Magnetic Curtains: Installation can often be completed in 2-4 hours. The impact on operations is negligible. Sliding Doors: The doorway will be out of commission for several days during installation, requiring logistical workarounds and potentially halting operations in that area.

The Final Verdict: A Procurement Decision Framework for Facility Managers

Decision Matrix: Scoring Each Solution Against Key B2B Criteria

After analyzing performance across energy, cost, operations, and maintenance, a clear decision-making framework emerges. The choice is not about which door is "better," but which door is *right* for the specific business goal and application.

| Procurement Criterion | Magnetic PVC Curtain | Traditional Sliding Door | Winner |

|---|---|---|---|

| Lowest Upfront Cost | ★★★★★ | ★☆☆☆☆ | Magnetic Curtain |

| Fastest ROI | ★★★★★ | ★★☆☆☆ | Magnetic Curtain |

| Energy Efficiency (High Traffic) | ★★★★★ | ★★★☆☆ | Magnetic Curtain |

| Operational Throughput | ★★★★★ | ★★★☆☆ | Magnetic Curtain |

| External Security | ★☆☆☆☆ | ★★★★★ | Sliding Door |

| Low Maintenance Cost | ★★★★★ | ★★☆☆☆ | Magnetic Curtain |

| Durability (Heavy Impact) | ★★★☆☆ | ★★★★☆ | Sliding Door |

| Ease of Installation | ★★★★★ | ★☆☆☆☆ | Magnetic Curtain |

A Quick-Reference Checklist for Your Next Warehouse Door Procurement

- Identify the Application: Is this an internal or external opening?

- Define Primary Goal: Is the top priority security, climate control, or workflow speed?

- Analyze Traffic: What is the volume and type of traffic (pedestrian, forklift)?

Final Recommendation: Matching the Right Door to Your Business Goals

For maximizing operational efficiency, achieving rapid ROI, and drastically reducing energy costs in high-traffic *internal* doorways—especially in climate-controlled environments—the Magnetic PVC Curtain is the superior-performing solution.

For securing *external* openings against intrusion and weather, especially for large vehicle access where robust durability is paramount, the Insulated Sliding Door remains the necessary and correct investment.

Frequently Asked Questions (FAQ)

What are the most energy-efficient industrial doors for warehouses?

For *internal* doorways with high traffic, **magnetic PVC strip curtains** are often the most energy-efficient choice. Their self-closing magnetic seal excels at preventing constant air exchange (convection). For *external* openings, a high-speed, **insulated sliding or rolling door** offers superior thermal insulation (R-value) but at a much higher cost.

How do magnetic PVC strip curtains contribute to cost savings in industrial facilities?

They deliver savings through: **Direct Energy Reduction** (up to 75%), **Lower Upfront Investment**, **Minimal Maintenance Costs**, and **Productivity Gains** from hands-free operation.

What are the key advantages of choosing sliding doors for large warehouse openings?

Sliding doors are preferred for large exterior openings for several key reasons: **Security**, **Durability**, **Space Efficiency**, and **Large Vehicle Access**.

How does regular maintenance impact the ROI of industrial warehouse doors?

For **sliding doors**, preventative maintenance is essential to prevent costly emergency repairs. For **magnetic curtains**, simple cleaning preserves visibility, and replacing worn strips extends the system's life, protecting the low-cost investment.

Which door is better for temperature and pest control?

For *internal* separation, **magnetic PVC curtains** are superior for both. For *external-facing* applications, a well-sealed, **insulated sliding door** is more effective, but a hybrid approach is often best.