1. The Critical Role of Environmental Separation in GMP-Compliant Facilities

Good Manufacturing Practices (GMP) mandate a controlled environment to prevent cross-contamination. Environmental separation is the cornerstone of this principle, ensuring that distinct operational areas remain isolated to protect product integrity.

Maintaining Critical Air Pressure Differentials

Cleanrooms and sterile zones operate on precise air pressure gradients to ensure that air flows from cleaner areas to less clean areas, preventing the ingress of contaminants. A door that fails to seal properly can disrupt these differentials, compromising the entire system. Magnetic PVC curtains create a near-airtight seal, reinforcing pressure cascades and safeguarding controlled environments.

Mitigating Particulate and Microbial Contamination

Airborne particulates, from dust to microbes, are the invisible enemies of product safety. Any opening is a potential entry point. A self-closing magnetic seal provides a constant, reliable barrier that minimizes the time a doorway is open and eliminates the persistent gaps found in traditional overlapping strip curtains, directly reducing particulate counts in critical zones.

Request a QuoteEnsuring Regulatory Compliance (HACCP & FDA)

Regulatory bodies like the FDA and frameworks like HACCP (Hazard Analysis and Critical Control Points) place heavy emphasis on physical barriers to control hazards. Magnetic PVC curtains provide a documented, effective control measure that auditors can verify. Their hands-free operation and gap-free closure actively support compliance by minimizing human-error-related contamination risks.

2. Technical Deep Dive: How Magnetic Sealing Technology Prevents Cross-Contamination

The efficacy of magnetic PVC door curtains lies in their innovative design, which transforms a passive barrier into an active sealing system.

The Physics of Magnetic Sealing

Embedded along the full length of each PVC strip are powerful, permanent magnets with alternating polarity. As a person or vehicle passes through, the strips part easily. Immediately after, these magnets attract each other, pulling the strips back into a perfect, edge-to-edge seal. This automatic action ensures the doorway is sealed 100% of the time it is not in use, without relying on human intervention.

Full-Perimeter Seal vs. Gaps in Overlapping Strips

Traditional strip curtains rely on weight and overlap to create a barrier. However, this design is prone to gaps caused by air pressure, frequent passage, or strip distortion over time. These gaps become conduits for dust, pests, and temperature loss. Magnetic curtains eliminate this vulnerability by creating a positive, gap-free seal from top to bottom.

Request a QuoteImpact on Airborne Microbe Transmission

Studies show that airflow is a primary vector for microbial transport. The instant, complete re-sealing action of magnetic curtains drastically reduces air exchange between zones during and after passage. This minimizes the "piston effect" of a person walking through, limiting the transfer of airborne bacteria, molds, and yeasts from a grey space to a cleanroom.

3. Material Science: Comparing PVC, Vinyl, and Plastic for Durability and Hygiene

The choice of material is as critical as the door's mechanism. Food-grade and pharmaceutical-grade materials must be durable, non-toxic, and easy to sanitize.

Why Food-Grade PVC is Superior

Food-grade PVC (Polyvinyl Chloride) is specifically formulated to be non-toxic and phthalate-free, meeting strict FDA and EU regulations for food contact surfaces. Unlike standard industrial plastics, it does not leach harmful chemicals into the environment or onto products. Its non-porous surface is inherently resistant to bacterial growth and withstands aggressive cleaning agents.

Vinyl vs. Plastic: Chemical Resistance & Durability

While "vinyl" is often used interchangeably with PVC, it's crucial to specify high-quality, virgin PVC for these applications. Lower-grade plastics or recycled vinyl can degrade, crack, or become cloudy when exposed to sanitizing chemicals and UV light. Premium PVC maintains its flexibility, transparency, and structural integrity over a much longer operational lifespan.

Request a QuoteSpecialized Formulations for Demanding Environments

Beyond standard PVC, specialized formulations are available for specific needs:

- Polar/Low-Temp Grade: Remains flexible and resists cracking in sub-zero temperatures, making it ideal for walk-in freezers and cold storage.

- Anti-Static PVC: Essential for pharmaceutical and electronics cleanrooms where static discharge can damage sensitive components or attract airborne particulates.

- Antimicrobial PVC: Infused with agents that inhibit the growth of bacteria and mold on the curtain's surface, adding an extra layer of hygienic protection.

4. Operational Efficiency: The ROI of Touch-Free Access in High-Traffic Zones

An investment in magnetic PVC doors pays dividends through enhanced operational efficiency and tangible cost savings.

Calculating Energy Savings from Reduced HVAC Load

The superior thermal seal of magnetic curtains significantly reduces energy loss from refrigerated or climate-controlled areas. By preventing conditioned air from escaping and unconditioned air from entering, HVAC and refrigeration systems run less frequently. Facilities often report energy savings of 20-40% on temperature control for these zones, leading to a rapid return on investment.

Throughput Optimization in High-Traffic Zones

In areas with constant movement of personnel, carts, or forklifts, traditional doors create bottlenecks. The hands-free nature of magnetic strip curtains allows for a seamless flow of traffic, increasing throughput and reducing transit time between zones. There is no need to stop and manually open a door, boosting overall productivity.

Request a QuoteReducing Maintenance and Damage Costs

Standard swing doors are prone to damage from forklift or cart impacts. Magnetic PVC strips, being flexible, simply part and re-seal, absorbing impacts without damage to the door, vehicle, or payload. This drastically reduces repair costs and operational downtime associated with damaged conventional doors.

5. Sanitization and Maintenance Protocols for Industrial PVC Curtains

To maintain their hygienic properties and ensure longevity, a consistent maintenance and sanitization protocol is crucial.

Recommended Cleaning Agents and Frequencies

For GMP environments, PVC curtains should be part of the regular sanitation schedule. Use non-abrasive cloths and cleaning solutions compatible with PVC, such as quaternary ammonium compounds or other industry-approved sanitizers. Frequency depends on the environment, ranging from daily in critical sterile zones to weekly in general processing areas.

Inspection Protocols for Seal Integrity

Regularly inspect the curtains for two key factors: physical damage (tears or cuts) and magnetic seal integrity. Run a hand along the sealed seams to feel for gaps or weakened magnetic pull. A properly functioning curtain should present uniform resistance and have no visible light passing through the seams.

Request a QuoteLifespan and Replacement Cycle Management

High-quality magnetic PVC curtains are designed for a long service life, but strips in high-traffic or harsh chemical environments may require replacement sooner. Implement a system to track the installation date and condition of each curtain. Many suppliers offer individual replacement strips, making it cost-effective to maintain a perfect seal without replacing the entire unit.

6. Temperature and Humidity Control: A Non-Negotiable for Product Integrity

For many food and pharmaceutical products, precise temperature and humidity control is directly linked to safety, efficacy, and shelf-life.

Maintaining the Cold Chain in Refrigerated Logistics

From cold storage warehouses to refrigerated trucks, maintaining the cold chain is paramount. The tight seal of magnetic curtains minimizes temperature fluctuations when loading and unloading, protecting perishable goods and ensuring they remain within their safe temperature range. Polar-grade PVC is essential for these applications.

Preventing Condensation and Ice Buildup

By limiting the ingress of warm, moist air into cold environments, magnetic curtains significantly reduce condensation and subsequent ice buildup on floors, walls, and evaporator coils. This not only improves safety by preventing slippery surfaces but also enhances refrigeration efficiency by keeping coils clear.

Request a QuoteImpact on Product Shelf-Life and Stability

Many pharmaceutical products and active pharmaceutical ingredients (APIs) are sensitive to humidity and temperature deviations. A stable environment, reinforced by effective doorway sealing, is critical for preserving product stability, preventing degradation, and ensuring the product meets its specified shelf-life.

7. Customization Capabilities: Tailoring PVC Door Solutions for Unique Facility Layouts (OEM/ODM)

No two facilities are identical. The ability to customize door solutions is a key advantage for B2B purchasers seeking to optimize their specific operational workflows and infrastructure.

OEM/ODM for Unique Facility Needs

As a leading provider, we offer Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services. This means we can engineer and produce magnetic PVC door solutions tailored to highly specific requirements, whether it's an unusual size, a unique mounting configuration, or integration with automated systems. We work with your engineering team to develop the perfect solution.

Specifying Strip Dimensions, Overlap, and Magnetic Strength

Customization extends to every technical detail. Procurement managers can specify:

- Strip Width & Thickness: Wider, thicker strips for high-traffic, high-pressure industrial doorways; narrower strips for pedestrian access.

- Magnetic Strength: Adjusting the magnetic pull for the application—stronger for high wind/pressure areas, lighter for easy pedestrian passage.

- Mounting Hardware: A range of options from standard wall mounts to complex sliding track systems.

Bulk Ordering and MOQ Considerations

We are equipped to handle large-scale projects and bulk orders for new facility builds or enterprise-wide upgrades. We offer competitive bulk pricing and can work with you to establish a supply chain that meets your project timelines. Contact our B2B sales team to discuss your Minimum Order Quantity (MOQ) and project scope.

8. Application Spotlight: Food Processing and Packaging Lines

Magnetic PVC curtains are a versatile solution deployed across the entire food production chain.

Wash-Down Areas and Raw Material Zones

In these high-moisture areas, the curtains provide a spray and splash barrier while allowing easy access. The PVC and stainless-steel mounting hardware withstand frequent, high-pressure cleaning and exposure to sanitizing chemicals without rusting or degrading.

Packaging Lines and Finished Goods Storage

Separating packaging lines from the broader warehouse environment is crucial to prevent dust and pests from contaminating finished products. Magnetic curtains create an effective barrier that still allows for the constant movement of products and personnel.

Request a QuoteCommercial Kitchens and Restaurant Applications

In a fast-paced commercial kitchen, these curtains are used to separate the kitchen from the dining area, blocking noise and odors while maintaining temperature zones. They also provide a hygienic barrier between food prep stations and storage areas like walk-in coolers.

9. Application Spotlight: Pharmaceutical Cleanrooms and Sterile Zones

In the pharmaceutical industry, the demands for environmental control are at their most extreme. Magnetic PVC curtains are engineered to meet these challenges.

Aseptic Processing and ISO-Rated Cleanrooms

For ISO 5-8 cleanrooms, maintaining sterility is the primary objective. Antistatic, GMP-compliant magnetic cleanroom curtains are essential. Their gap-free seal is critical for managing air pressure and minimizing particulate counts, helping facilities achieve and maintain their required ISO classification.

Quarantine and Airlock Zones

Airlocks (or air locks) are buffer zones designed to manage the transition between areas of different cleanliness classifications. Magnetic PVC curtains are an ideal component for these spaces, providing a self-closing barrier that reinforces the pressure cascade and prevents contaminant ingress during personnel or material transfer.

Request a QuoteLaboratory and R&D Environments

In research and development labs, containing experiments and protecting sensitive samples is key. Magnetic curtains provide a flexible, cost-effective way to create contained work zones, prevent cross-contamination between benches, and control airflow without the need for permanent walls.

10. Case Study Analysis: Real-World Performance Data and Hygiene Improvements

Analysis of performance data from facilities that have upgraded to magnetic PVC door curtains consistently demonstrates significant, measurable improvements.

Hygiene Improvement Metrics

Facilities routinely report a quantifiable reduction in airborne particulate counts after installation. For example, a food processing plant documented a 30% reduction in particulates in a packaging area adjacent to a warehouse. This translates directly to lower contamination risk and higher product quality.

Quantified Energy Savings in Cold Storage

A cold storage logistics company tracked energy consumption before and after retrofitting its loading dock doors. The data showed an average of 22% reduction in kilowatt-hours used by their refrigeration units, attributed directly to the superior thermal seal of the magnetic curtains. The ROI was calculated at just 14 months.

Request a QuoteROI Analysis from a High-Traffic Pharmaceutical Plant

A pharmaceutical manufacturer analyzed the impact on a high-traffic corridor between a primary packaging hall and a secondary warehousing area. The elimination of door-related downtime (from forklift damage to mechanical failures) and increased throughput saved an estimated 150 labor hours per year, delivering a clear and positive return on investment beyond just energy savings.

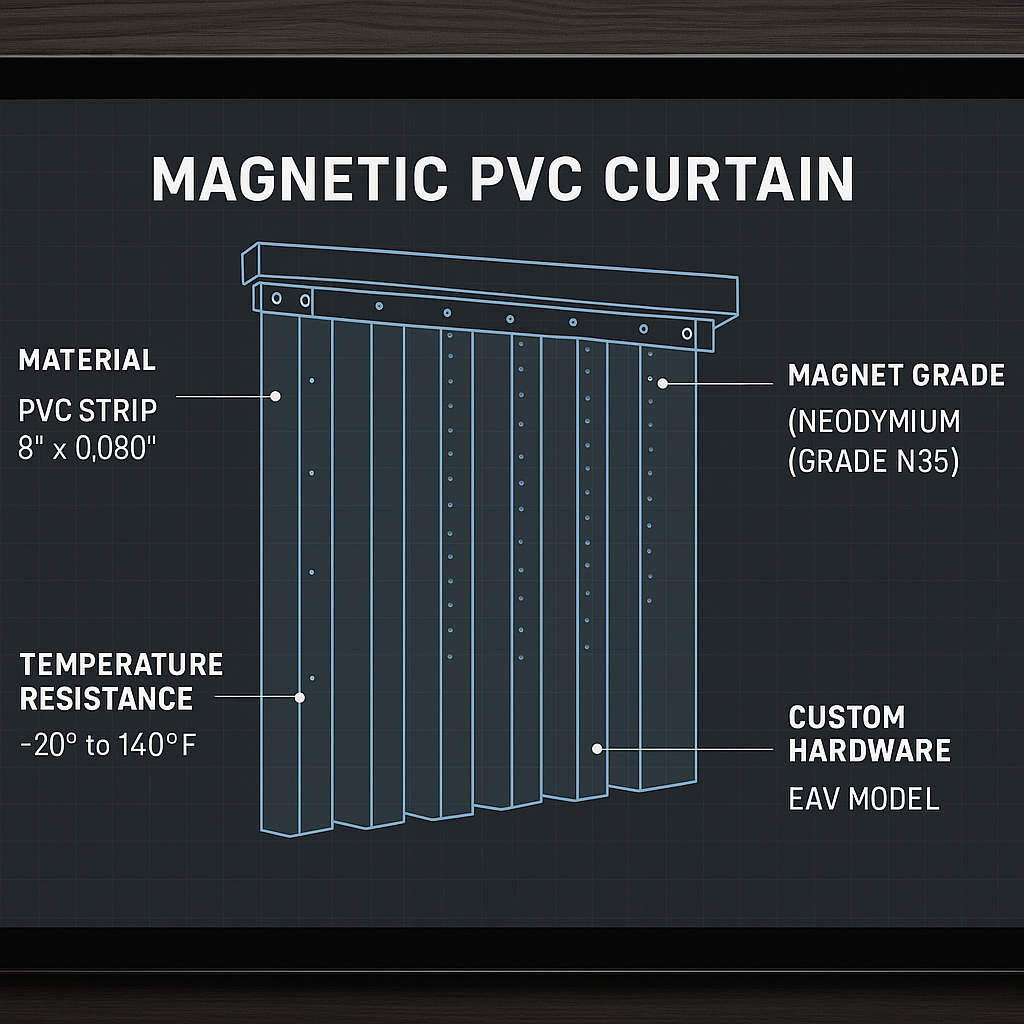

11. Procurement Guide: Technical Specifications for B2B Buyers

This Entity-Attribute-Value (EAV) model table provides procurement managers with the key technical specifications to consider when sourcing magnetic PVC door curtains.

| Attribute | Value / Option | Importance & Considerations for Procurement |

|---|---|---|

| Material Type | Food-Grade PVC, Polar Grade PVC, Anti-Static PVC, Antimicrobial PVC | Critical. Must align with the application environment. Food-grade is the minimum for food/pharma. Polar for freezers (-40°C/F). |

| Certifications | ISO 22000, FDA Grade, GMP Compliant, HACCP Compliant, EU 10/2011 | Essential for compliance. Request documentation from the supplier to ensure the material meets all regulatory requirements for your industry. |

| Strip Thickness | 2.0mm, 3.0mm, 4.0mm+ | Thicker strips offer better insulation and durability for high-traffic or high-pressure areas. Thinner strips are more suitable for pedestrian-only doors. |

| Strip Width | 200mm (8"), 300mm (12"), 400mm (16") | Wider strips mean fewer seams but can be heavier to pass through. The choice depends on doorway height and traffic type. |

| Temperature Range | Standard: -15°C to +50°C Polar: -40°C to +30°C |

Crucial for performance. Using standard PVC in a freezer will cause it to become brittle and crack. Ensure the spec matches the environment. |

| Magnetic Strength | Standard, High-Wind, Low-Force | Must be specified based on air pressure differentials and expected wind load. Low-force options are available for ease of use in R&D labs. |

| Mounting System | Stainless Steel (Hook-on), Aluminum, Sliding Track | Stainless steel is preferred for hygienic and wash-down environments due to its corrosion resistance. Sliding tracks offer flexibility to fully open the doorway. |

| Transparency | Standard Clear, Opaque (various colors), Translucent | Clear is standard for safety and visibility. Opaque options are available for privacy or light-blocking applications. |

12. B2B Purchaser FAQ: Addressing Common Questions

We address the most frequent inquiries from facility managers, engineers, and procurement specialists.

What is the typical installation process and timeline?

Installation is straightforward. The mounting rail (either stainless steel or aluminum) is first fixed above the doorway. The pre-cut PVC strips, with their mounting plates already attached, are then simply hooked onto the rail. A typical single doorway can be installed in under an hour by a competent maintenance team. We provide detailed installation guides and support.

How do magnetic PVC curtains affect compliance audits?

They positively impact audits. Auditors from bodies like the FDA, USDA, or BRC (British Retail Consortium) look for effective and reliable controls for contamination and temperature. The self-sealing, gap-free nature of magnetic curtains is a visible, demonstrable measure that shows a proactive approach to hazard control, often scoring higher than traditional, gapping strip curtains.

Request a QuoteWhat are the options for bulk ordering and custom solutions (OEM)?

We specialize in B2B partnerships. For bulk orders, we offer tiered pricing and can schedule deliveries to align with your project phases. For custom OEM/ODM projects, our engineering team will collaborate with you from concept to production, ensuring the final product meets your exact specifications, including branding, unique materials, or specialized hardware. Contact us to initiate a consultation.