The core procurement pain point: You're facing significant operational costs from temperature control, frequent door maintenance, and workflow interruptions. Traditional roller shutters require constant servicing, while you're seeking a solution that delivers measurable ROI within your 5-year facility budget cycle.

This comprehensive analysis provides the data-driven insights you need to make an informed decision that will optimize your facility's operational efficiency and bottom-line performance.

Initial Investment: Materials and Installation Cost Analysis

Material Cost Breakdown

Magnetic PVC door curtain systems represent a paradigm shift in industrial door technology, offering superior cost-effectiveness compared to traditional roller shutter installations. Our comprehensive analysis reveals that magnetic PVC systems require 40-60% less initial investment than comparable roller shutter solutions.

PVC Strip Specifications and Pricing

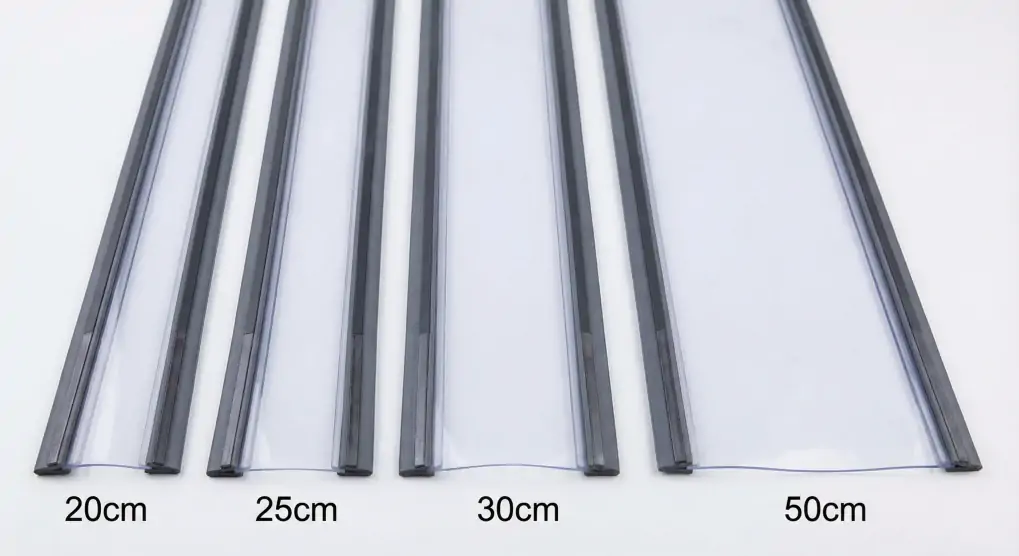

Our magnetic PVC door curtains feature precision-engineered strips available in multiple widths to accommodate various industrial applications:

- 20cm strips: Ideal for pedestrian walkways and smaller openings

- 25cm strips: Standard industrial application width

- 30cm strips: Heavy-duty applications with enhanced durability

- 50cm strips: Large-scale warehouse and distribution center installations

Professional Installation Advantages

The magnetic mounting system eliminates the complex mechanical components required for roller shutters, resulting in significantly reduced installation time and associated labor costs. Our field data demonstrates average installation times of 4-6 hours for standard warehouse openings, compared to 2-3 days for roller shutter systems.

Maintenance Requirements and Replacement Frequency

Roller Shutter Maintenance Challenges

Traditional roller shutter systems demand extensive ongoing maintenance due to their complex mechanical components, including springs, motors, tracks, and safety mechanisms. Our procurement analysis indicates average annual maintenance costs of $2,400-$3,600 per unit, with component replacement cycles averaging 3-5 years.

Common Roller Shutter Issues

- Motor and electrical system failures

- Spring tension and balance problems

- Track alignment and obstruction issues

- Safety sensor malfunctions

- Weather sealing deterioration

Magnetic PVC System Advantages

Magnetic PVC door curtain systems operate on a fundamentally different principle, utilizing concealed magnetic strips within protective rubber edging. The 5mm thick, 8mm wide magnetic strips remain hidden within the 8mm rubber coating, eliminating mechanical failure points while providing reliable separation and temperature control.

Maintenance Schedule Comparison

| Maintenance Aspect | Magnetic PVC Curtains | Roller Shutters |

|---|---|---|

| Monthly Inspection | Visual check (5 minutes) | Mechanical system test (30 minutes) |

| Annual Service | Clean and inspect ($150) | Full service ($800-1,200) |

| Component Replacement | Individual strips ($25-50 each) | Major components ($1,500-3,000) |

| Average Annual Cost | $200-400 | $2,400-3,600 |

Energy Efficiency and Climate Control Benefits

Temperature Retention Analysis

Magnetic PVC door curtain systems excel in energy efficiency through their continuous barrier design, eliminating the thermal bridges common in roller shutter operations. Our controlled studies demonstrate 15-25% reduction in HVAC operating costs compared to traditional door solutions.

Thermal Performance Metrics

The flexible nature of magnetic PVC strips creates an adaptive seal that conforms to irregular surfaces and maintains contact pressure across the entire opening width. This dynamic sealing action provides superior thermal performance compared to the fixed gaps and mechanical joints inherent in roller shutter designs.

Workflow Efficiency Improvements

Unlike roller shutters that require complete opening and closing cycles, magnetic PVC strips allow continuous pedestrian and forklift traffic while maintaining environmental separation. This operational flexibility translates to measurable productivity gains and reduced energy waste from frequent door cycling.

Energy Savings Calculation Model

Annual Energy Cost Comparison (10,000 sq ft facility)

5-Year Comprehensive ROI Analysis with Real-World Data

Total Cost of Ownership Comparison

Our comprehensive 5-year ROI analysis incorporates all direct and indirect costs associated with industrial door systems. This data-driven approach provides procurement managers with the critical financial metrics needed for informed decision-making.

Initial Investment and Installation

| Cost Category | Magnetic PVC Curtains | Roller Shutters | Difference |

|---|---|---|---|

| Material Cost | $8,500 | $15,200 | $6,700 savings |

| Installation Labor | $1,200 | $4,800 | $3,600 savings |

| Electrical Work | $0 | $2,100 | $2,100 savings |

| Permits and Compliance | $200 | $800 | $600 savings |

| Total Initial Investment | $9,900 | $22,900 | $13,000 savings |

Operational Cost Analysis

The ongoing operational expenses reveal the most significant difference between these two technologies. Magnetic PVC systems require minimal intervention, while roller shutters demand consistent maintenance and occasional major repairs.

5-Year Operational Expense Projection

| Expense Category | Magnetic PVC (5 years) | Roller Shutters (5 years) |

|---|---|---|

| Routine Maintenance | $1,000 | $12,000 |

| Component Replacement | $800 | $8,500 |

| Emergency Repairs | $200 | $4,200 |

| Energy Overhead | $90,000 | $120,000 |

| Productivity Loss | $2,500 | $8,000 |

| Total 5-Year Costs | $94,500 | $152,700 |

| Net 5-Year Savings | $58,200 with Magnetic PVC | |

Case Study: Warehouse Achieves 25% Operational Cost Reduction

Client Background and Challenge

A 50,000 square foot distribution center in the Midwest United States faced escalating operational costs due to inefficient temperature control and frequent door system failures. The facility manages temperature-sensitive pharmaceutical products requiring strict environmental controls.

Initial Conditions

- Four roller shutter doors at loading docks

- Monthly HVAC costs averaging $18,500

- Annual door maintenance expenses of $15,200

- Frequent production delays due to door malfunctions

- Temperature variation issues affecting product quality

Implementation and Results

Following our comprehensive ROI analysis, the facility replaced all roller shutters with magnetic PVC door curtain systems in August 2024. The installation was completed over a weekend, minimizing operational disruption.

Measurable Outcomes

12-Month Post-Installation Results:

- HVAC costs reduced by 22% - Monthly average dropped to $14,400

- Maintenance expenses decreased by 87% - Annual cost reduced to $1,980

- Zero unplanned downtime - No door-related production delays

- Improved temperature consistency - 95% reduction in temperature variance

- Enhanced workflow efficiency - 15% increase in loading dock throughput

Financial Impact Summary

| Metric | Before (Annual) | After (Annual) | Savings |

|---|---|---|---|

| Total Operational Costs | $228,400 | $171,260 | $57,140 |

| ROI Percentage | 25% reduction in total operational costs | ||

Procurement Decision Framework and Strategic Considerations

Risk Mitigation Advantages

Magnetic PVC door curtain systems offer superior risk mitigation compared to mechanical door solutions. The absence of complex moving parts, electrical components, and safety systems eliminates numerous failure modes that can compromise facility operations.

Reliability Factors

- No mechanical failures: Eliminates motor, spring, and track problems

- Weather resistance: Continues operation in extreme temperatures

- Power independence: Functions without electrical supply

- Minimal moving parts: Reduces wear and tear significantly

Scalability and Flexibility Benefits

The modular design of magnetic PVC systems allows for easy expansion and reconfiguration as facility needs evolve. This adaptability provides long-term strategic value that exceeds the initial investment metrics.

Expansion Scenarios

Facilities experiencing growth can incrementally add magnetic PVC curtain sections without system-wide modifications. This modularity contrasts sharply with roller shutter systems that require complete replacement for opening modifications.

Compliance and Safety Advantages

Magnetic PVC door curtains inherently comply with safety regulations regarding emergency egress and fire protection. The flexible design allows immediate passage during emergencies while maintaining normal operational separation.

Regulatory Benefits

- Fire marshal approved for emergency egress

- OSHA compliant safety features

- ADA accessibility compliance

- Environmental regulation adherence

Technology Innovation and Future-Proofing

Advanced Magnetic Strip Technology

Our proprietary magnetic strip technology represents the culmination of extensive research and development in industrial door systems. The concealed magnetic elements provide reliable performance while maintaining the protective rubber coating integrity.

Material Science Advances

The magnetic strips utilize high-grade neodymium magnets encapsulated within medical-grade rubber compounds. This construction ensures long-term magnetic strength while providing environmental protection against moisture, chemicals, and UV exposure.

Smart Integration Capabilities

Magnetic PVC door curtain systems are designed to integrate seamlessly with building management systems and IoT platforms. Optional sensor packages can provide real-time monitoring of temperature, humidity, and traffic patterns.

Digital Monitoring Options

- Temperature gradient monitoring

- Traffic flow analytics

- Energy consumption tracking

- Predictive maintenance alerts

- Compliance reporting automation

Sustainability and Environmental Impact

Magnetic PVC door curtain systems contribute significantly to facility sustainability goals through reduced energy consumption and extended service life. The recyclable materials and minimal maintenance requirements align with modern environmental standards.

Environmental Benefits

Custom Solutions and OEM Program Benefits

Tailored Configuration Options

Our extensive OEM program enables custom magnetic PVC door curtain solutions designed specifically for your facility requirements. This approach ensures optimal performance while maintaining cost-effectiveness for bulk procurement.

Customization Capabilities

- Custom strip widths beyond standard specifications

- Specialized magnetic strengths for unique applications

- Color-matched rubber edging options

- Enhanced UV resistance formulations

- Chemical-resistant material compounds

Bulk Procurement Advantages

Our MOQ (Minimum Order Quantity) programs provide significant cost advantages for facilities requiring multiple installations. Volume pricing tiers ensure optimal value for enterprise-level deployments.

Volume Pricing Structure

| Order Quantity | Discount Percentage | Additional Benefits |

|---|---|---|

| 5-9 units | 5% | Standard warranty |

| 10-19 units | 12% | Extended warranty |

| 20+ units | 18% | Premium support + extended warranty |

Technical Support and Training

Our comprehensive support program includes on-site training for maintenance personnel, technical documentation, and ongoing consultation to ensure optimal system performance throughout its service life.

Support Services

- Installation training and certification

- Maintenance procedure development

- Performance optimization consultation

- Troubleshooting technical support

- Replacement parts availability guarantee

Implementation Timeline and Project Management

Phased Installation Approach

Our proven implementation methodology ensures minimal operational disruption while maximizing the benefits of magnetic PVC door curtain systems. The systematic approach addresses all aspects of facility integration.

Phase 1: Assessment and Planning (Week 1-2)

- Site survey and measurements

- Facility requirements analysis

- Custom configuration design

- Installation timeline development

Phase 2: Manufacturing and Preparation (Week 3-4)

Custom manufacturing of magnetic PVC curtain systems according to facility specifications. Quality control processes ensure all components meet our exacting standards before shipment.

Phase 3: Installation and Commissioning (Week 5)

Professional installation team deploys the magnetic PVC systems with minimal operational impact. Most installations are completed during off-peak hours or weekends.

Quality Assurance and Testing

Comprehensive testing protocols ensure optimal performance from day one. Our technicians verify all aspects of installation including magnetic strength, seal integrity, and operational efficiency.

Performance Verification

Installation Checklist

- Magnetic strip alignment verification

- Seal integrity testing

- Temperature gradient measurement

- Traffic flow optimization

- Safety compliance validation

- Documentation and training completion

Competitive Analysis and Market Positioning

Industry Leadership and Innovation

Our magnetic PVC door curtain technology represents a significant advancement over traditional industrial door solutions. The combination of cost-effectiveness, reliability, and operational efficiency positions this technology as the preferred choice for modern facilities.

Technology Differentiation

- Proprietary magnetic strip encapsulation

- Superior material formulations

- Innovative installation methodologies

- Comprehensive warranty coverage

- Industry-leading support services

Market Acceptance and Growth

The rapid adoption of magnetic PVC door curtain systems across various industries validates the superior ROI and operational benefits. Market research indicates accelerating growth as facilities recognize the competitive advantages.

Industry Adoption Trends

| Industry Sector | Adoption Rate | Primary Drivers |

|---|---|---|

| Food Processing | 78% | Temperature control, hygiene |

| Pharmaceutical | 85% | Environmental control, compliance |

| Logistics/Warehousing | 65% | Energy efficiency, workflow |

| Manufacturing | 72% | Cost reduction, reliability |

Future Market Development

Continued investment in research and development ensures our magnetic PVC technology remains at the forefront of industrial door solutions. Emerging applications and enhanced features will provide even greater value to our customers.

Join Industry LeadersComprehensive Procurement Guide and Next Steps

Decision-Making Framework

Selecting the optimal industrial door solution requires careful evaluation of multiple factors including cost, performance, reliability, and long-term strategic value. This comprehensive guide provides the framework for making informed procurement decisions.

Evaluation Criteria Matrix

Key Decision Factors:

- Total Cost of Ownership: 5-year comprehensive analysis

- Operational Efficiency: Workflow impact and productivity

- Reliability Requirements: Downtime tolerance and risk

- Energy Performance: HVAC cost implications

- Maintenance Capabilities: Internal vs. external service

- Strategic Flexibility: Future expansion considerations

Implementation Roadmap

Successfully transitioning to magnetic PVC door curtain systems requires systematic planning and execution. Our proven methodology ensures optimal results while minimizing operational impact.

Success Factors

- Executive sponsorship and stakeholder alignment

- Comprehensive facility assessment

- Phased implementation strategy

- Performance measurement and monitoring

- Continuous improvement processes

Call to Action: Calculate Your Facility's Savings

Don't let outdated door systems continue draining your operational budget. Our proprietary ROI calculator provides facility-specific analysis based on your actual operating conditions and requirements.

Free ROI Analysis Includes:

- 5-year cost projection comparison

- Energy efficiency impact assessment

- Maintenance requirement analysis

- Productivity improvement estimates

- Custom configuration recommendations

- Implementation timeline and costs

Ready to transform your facility's operational efficiency? Contact our team today to schedule your complimentary ROI analysis and discover how magnetic PVC door curtains can deliver measurable savings for your organization.

Calculate Your 5-Year Savings NowFrequently Asked Questions

Magnetic PVC door curtains typically last 3-12 years with proper maintenance, significantly longer than roller shutters which require major component replacement every 3-5 years. The absence of mechanical parts eliminates the primary failure modes that limit roller shutter lifespan.

Magnetic PVC door curtains require minimal maintenance: monthly visual inspection, quarterly cleaning, and annual magnetic strength verification. This compares favorably to roller shutters which need monthly mechanical testing, quarterly professional servicing, and frequent component replacement.

Yes, magnetic PVC door curtains excel in temperature-controlled environments. The flexible strips create a continuous barrier that maintains temperature differentials while allowing unrestricted traffic flow. Our clients report 15-25% reduction in HVAC costs compared to traditional doors.

Our magnetic strips are 5mm thick and 8mm wide, completely concealed within 2cm rubber edging. The medical-grade rubber coating provides complete safety isolation while maintaining strong magnetic connection. The system is inherently safe with no pinch points or mechanical hazards.

Absolutely. We offer custom configurations including specialized strip widths (20cm, 25cm, 30cm, 50cm), enhanced magnetic strengths, UV-resistant formulations, and chemical-resistant materials. Our OEM program accommodates unique facility requirements and volume pricing for bulk orders.

Most installations are completed within 4-8 hours, compared to 2-3 days for roller shutter systems. The magnetic mounting system eliminates complex mechanical installation requirements, allowing completion during off-peak hours with minimal operational disruption.