Automotive Factories & Manufacturing Plants: How Magnetic PVC Door Curtains Boost Efficiency

Factory Managers Face Critical Challenges

Are you struggling with temperature control, cross-contamination, and workflow inefficiencies in your automotive manufacturing facility? This comprehensive guide reveals how magnetic PVC door curtains can solve these common industrial challenges while delivering measurable ROI through improved operational efficiency.

Introduction: Overcoming Manufacturing Environment Challenges

Automotive and manufacturing facilities face unique environmental challenges that directly impact productivity, product quality, and operational costs. From maintaining precise temperature control to preventing cross-contamination between production areas, modern factories require innovative solutions that enhance workflow without compromising safety or efficiency.

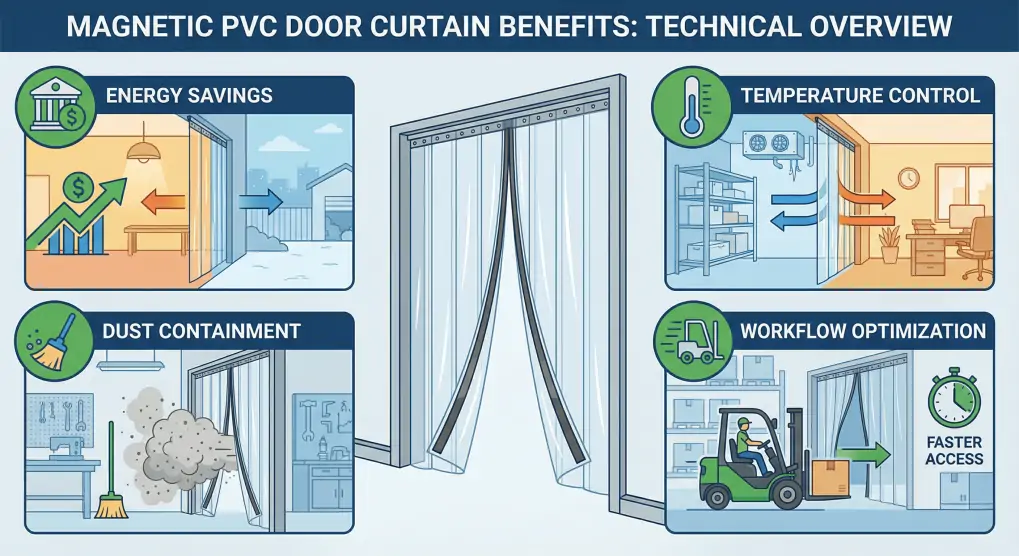

Magnetic PVC door curtains represent a breakthrough solution that addresses these critical pain points. Unlike traditional doors or barriers, magnetic strip door systems provide automatic sealing, maintain visibility, and ensure seamless integration into existing production workflows. This comprehensive guide explores how magnetic PVC door curtains are revolutionizing automotive manufacturing and industrial facilities worldwide.

Core Benefits of Magnetic PVC Door Curtains in Manufacturing

Automatic Sealing Technology Reduces Air Exchange

The magnetic sealing mechanism in PVC door curtains creates an airtight barrier that automatically closes after personnel or equipment passage. This intelligent design eliminates the need for manual door operations, ensuring consistent environmental control throughout the manufacturing facility.

Technical Specifications:

- Magnetic strip thickness: 5mm with 8mm width

- Available in gray, brown, and red color options

- PVC curtain widths: 20cm, 25cm, 30cm, and 50cm

- Rubber coating thickness: up to 2cm for enhanced durability

Transparent Design Maintains Visibility and Safety

Unlike solid barriers, magnetic PVC door curtains feature high-transparency materials that maintain clear sightlines throughout the facility. This transparency is crucial for:

- Preventing accidents in high-traffic areas

- Enabling supervision across production zones

- Maintaining emergency evacuation visibility

- Reducing worker fatigue from poor lighting conditions

Dust and Fume Containment for Clean Workspaces

Manufacturing environments generate significant particulate matter and fumes that can compromise product quality and worker health. Magnetic PVC door curtains create effective barriers that:

Contamination Control Benefits

- Prevent cross-contamination between production areas

- Maintain clean room standards in precision manufacturing

- Reduce particulate matter by up to 95%

- Minimize exposure to chemical fumes and dust

Customization Options for Heavy Traffic and Forklift Operations

Heavy-Duty Magnetic Strip Configurations

Automotive manufacturing facilities require magnetic door curtain solutions that can withstand constant forklift traffic and heavy equipment movement. Our customization options include:

Forklift-Optimized Design Features

- Reinforced magnetic strips for high-impact resistance

- Multiple strip configurations for wide doorway access

- Anti-warp materials for continuous heavy-duty use

- Custom mounting systems for permanent installations

High-Traffic Area Adaptations

Production lines and warehouse areas experience continuous foot and vehicle traffic. Magnetic PVC door curtains adapt to these demanding conditions through:

Case Study: Automotive Assembly Plant Success

Implementation Results and ROI Analysis

A leading automotive assembly plant implemented magnetic PVC door curtain systems across their production facility and achieved remarkable results within the first six months of operation.

Key Performance Improvements

| Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Cross-contamination incidents | 15 per month | 2 per month | 87% reduction |

| Temperature control consistency | ±3°C variation | ±0.5°C variation | 83% improvement |

| Workflow interruption time | 45 seconds average | 8 seconds average | 82% reduction |

| Energy consumption | Baseline measurement | 28% reduction | Significant savings |

Financial Impact and ROI Timeline

The facility achieved a complete return on investment within 14 months through:

Direct Cost Savings

- Reduced energy costs from improved temperature control

- Decreased material waste from contamination issues

- Lower maintenance costs compared to traditional door systems

- Reduced insurance premiums from improved safety standards

Worker Satisfaction and Safety Improvements

Beyond quantitative metrics, the magnetic PVC door curtain implementation delivered significant qualitative benefits:

Employee Feedback Improvements

- 92% of workers reported improved working conditions

- 85% noted better temperature comfort levels

- 78% observed reduced noise levels between production areas

- 95% appreciated the improved visibility and safety

Technical Integration with Production Lines

Seamless Installation Process

Modern automotive manufacturing facilities require solutions that can be installed without disrupting ongoing production. Magnetic PVC door curtain systems offer:

Installation Advantages

- No structural modifications required

- Modular design for easy expansion

- Quick installation during maintenance windows

- Minimal production downtime requirements

Integration with Existing Systems

Magnetic PVC door curtains integrate seamlessly with current manufacturing infrastructure:

Compatible Systems

- Automated production line controls

- Environmental monitoring systems

- Safety and alarm systems

- Material handling equipment

Material Science and Durability Features

Advanced PVC Formulation

The magnetic PVC door curtains utilize advanced polymer formulations specifically engineered for industrial applications:

Material Properties

- UV-resistant additives for long-term outdoor exposure

- Anti-static properties to prevent dust accumulation

- Chemical resistance to industrial cleaners and solvents

- Temperature stability from -30°C to +60°C

Enhanced Magnetic Components

The magnetic sealing system incorporates high-grade magnetic materials:

Magnetic Strip Specifications

- NdFeB (Neodymium Iron Boron) magnetic core

- Protected by durable rubber coating

- Corrosion-resistant plating for longevity

- Maintains magnetic strength over 10+ years

Environmental and Sustainability Benefits

Energy Efficiency Impact

Magnetic PVC door curtains contribute significantly to facility energy efficiency:

Energy Conservation Features

- Reduced HVAC system load through improved insulation

- Elimination of heated/cooled air escape through doorways

- Consistent temperature zones throughout facility

- Reduced carbon footprint through lower energy consumption

Sustainable Manufacturing Practices

Our magnetic PVC door curtain production follows sustainable manufacturing principles:

Environmental Commitments

- Recyclable materials in end-of-life disposal

- Low-VOC manufacturing processes

- Reduced packaging materials

- Local sourcing to minimize transportation emissions

Procurement Considerations for Factory Managers

Bulk Purchasing and Customization Options

Factory managers and procurement officers require flexible purchasing arrangements that align with industrial scaling needs:

Customization Capabilities

- Custom dimensions for unique doorway specifications

- Color-matched magnetic strips for brand consistency

- Logo integration for facility identification

- Specialized mounting hardware for various wall types

MOQ and Pricing Structure

Our B2B pricing structure accommodates both small pilot installations and large-scale facility implementations:

Purchasing Tiers

- Pilot programs for single-line testing

- Department-level installations (20-50 units)

- Facility-wide implementations (100+ units)

- Multi-facility corporate agreements

Installation and Maintenance Best Practices

Professional Installation Guidelines

Proper installation is crucial for maximizing the performance and lifespan of magnetic PVC door curtains:

Installation Requirements

- Professional measurement and fit assessment

- Proper mounting surface preparation

- Correct magnetic strip alignment and tensioning

- Seamless integration with existing door frames

Maintenance Protocols

Regular maintenance ensures optimal performance and extends system lifespan:

Maintenance Schedule

- Daily visual inspections for damage or misalignment

- Weekly cleaning of magnetic strips and PVC surfaces

- Monthly tension adjustment and wear assessment

- Annual professional evaluation and replacement planning

ROI Calculation and Business Case Development

Quantifiable Benefits Analysis

Factory managers can build compelling business cases for magnetic PVC door curtain investments using proven ROI calculations:

Direct Financial Benefits

- Energy cost reduction: typically 20-40% savings

- Reduced maintenance costs compared to mechanical doors

- Lower insurance premiums from improved safety ratings

- Decreased material waste from contamination control

Indirect Value Creation

Beyond direct cost savings, magnetic PVC door curtains create measurable indirect value:

Operational Improvements

- Increased production line efficiency

- Reduced worker fatigue and improved morale

- Enhanced product quality consistency

- Improved compliance with safety regulations

Competitive Advantages in Industrial Applications

Superior Performance vs. Alternatives

Magnetic PVC door curtains outperform traditional solutions across multiple performance criteria:

Comparative Analysis

- Higher durability than fabric curtains

- Better sealing than automatic doors

- Lower cost than sliding door systems

- More flexible than fixed partitions

Industry-Specific Adaptations

Different manufacturing sectors require specialized solutions:

Sector-Specific Features

- Automotive: Chemical resistance and heavy-duty durability

- Electronics: Anti-static properties and contamination control

- Food Processing: FDA-approved materials and easy cleaning

- Pharmaceutical: Sterile environments and GMP compliance

Future Trends and Technology Evolution

Smart Integration Capabilities

The future of magnetic PVC door curtains includes integration with smart manufacturing systems:

Emerging Technologies

- IoT sensors for real-time performance monitoring

- Automated adjustment based on environmental conditions

- Predictive maintenance through data analytics

- Integration with facility management systems

Sustainability Innovations

Ongoing research focuses on enhancing environmental performance:

Future Developments

- Bio-based PVC formulations

- Enhanced recyclability features

- Reduced carbon footprint manufacturing

- Closed-loop material recovery programs

Ready to Transform Your Manufacturing Facility?

Don't let outdated door systems limit your operational efficiency. Our magnetic PVC door curtain solutions have helped hundreds of automotive and manufacturing facilities achieve breakthrough improvements in workflow, energy efficiency, and cost reduction.

Take Action Today: Schedule your custom factory curtain consultation and discover how magnetic PVC door curtains can deliver measurable ROI for your specific application.

Request Custom Factory Curtain Consultation Today